In today’s fast-paced business environment, effective logistics optimization is essential for organizations striving to enhance their operational efficiency and maintain a competitive edge. This guide aims to explore the concept of logistics optimization and provide practical insights for implementing it in your business. We will begin by exploring what logistics optimization entails delving into the numerous benefits that effective logistics optimization can offer. Next, we will outline the critical stages of logistics optimization, providing a structured approach to streamline your processes. Finally, we will introduce seven essential diagrams designed to facilitate effective logistics optimization, enabling you to visualize and implement strategies that unlock efficiency within your supply chain. Whether you are a logistics professional or a business leader, this guide will equip you with the knowledge and tools necessary to enhance your logistics operations and drive success.

What Is Logistics Optimization?

Logistics optimization is a systematic approach focused on maximizing the efficiency and effectiveness of logistics and supply chain operations. This process involves refining logistics workflows to ensure timely and complete order deliveries, strategically using resources to reduce waste, and controlling costs. As global consumer expectations rise, logistics optimization has grown crucial for businesses striving to enhance operational efficiency and stay competitive. Given that logistics expenses make up a significant portion of total supply chain costs, optimizing logistics processes is essential for businesses aiming to streamline operations, meet demand, and sustain profitability in today’s competitive landscape.

Why Is Logistics Optimization Important in Today’s Market?

The importance of logistics optimization for modern businesses cannot be overstated. Without optimized logistics processes, companies risk longer delivery times, inflated costs, and potential issues with customer satisfaction. By implementing strategies such as route optimization, real-time visibility, and advanced technology integration, businesses can create a streamlined logistics operation that not only minimizes shipping costs but also elevates customer experience. Key approaches like demand management and insights from logistics process mapping enable companies to adopt optimization strategies more effectively. Optimizing logistics is not merely about reducing costs—it’s a means of strengthening a business’s competitive edge and enhancing its market standing, making logistics optimization a critical strategic priority in today’s landscape.

Benefits of Logistics Optimization

Logistics optimization is essential for businesses aiming to enhance their operational efficiency and competitiveness. By refining supply chain processes, companies can achieve various benefits that not only lower costs but also improve service quality and customer satisfaction. Here are five key advantages of implementing logistics optimization:

- Cost Reduction and Efficiency

Logistics optimization significantly reduces costs and improves efficiency, crucial for maintaining a competitive edge. By streamlining supply chain processes, businesses can lower transportation and storage costs. Techniques like route optimization and real-time fleet management minimize fuel consumption and labor expenses, leading to overall savings.

- Improved Customer Satisfaction

Optimized logistics enhances customer satisfaction by ensuring accurate and timely deliveries. With precise delivery windows and improved communication, companies can reduce missed deliveries, fostering brand loyalty and minimizing return rates. This customer-centric approach ultimately results in a better overall experience.

- Enhanced Resource Utilization

By optimizing logistics, businesses can better utilize their existing resources. Advanced analytics and performance data help identify inefficiencies, allowing companies to refine operations and allocate resources more effectively, leading to increased productivity.

- Faster Delivery Times

Efficient logistics processes contribute to faster delivery times, which drive higher-order accuracy. As businesses streamline their operations, they can respond more quickly to customer demands, enhancing service levels and improving customer retention.

- Increased Flexibility and Responsiveness

Logistics optimization enables businesses to be more flexible and responsive to market changes. By utilizing data-driven insights, companies can quickly adapt their logistics strategies to shifting consumer demands, supply chain disruptions, or changing market conditions, ensuring they remain agile in a competitive landscape.

7 Stages of Logistics Optimization

Logistics optimization is a structured process that involves multiple stages, each critical to enhancing operational efficiency and effectiveness. By following these stages, businesses can systematically improve their logistics performance, reduce costs, and enhance customer satisfaction. Here are the key stages of logistics optimization:

1. Define the Optimization Goal

Defining the optimization goal is the foundational step in logistics optimization. Organizations should establish clear, measurable objectives that align with their overall business strategy. These goals may include reducing logistics costs, improving delivery speed, enhancing customer satisfaction, or increasing inventory turnover. By setting specific targets, businesses can focus their efforts on achieving tangible improvements in their logistics operations.

2. Study the Current Logistics Performance Data

This stage involves a thorough analysis of existing logistics performance data to gain insights into the current state of operations. Businesses should examine historical performance metrics, such as delivery times, costs, and customer feedback, to identify patterns and areas for improvement. Understanding the current logistics landscape helps organizations recognize strengths to build upon and weaknesses that need addressing, laying the groundwork for effective optimization strategies.

3. Set Up Logistics Metrics & KPIs

Establishing key performance indicators (KPIs) is crucial for measuring the success of logistics optimization efforts. Important metrics to monitor include average delivery time, on-time delivery rate, safety ratings, customer complaints and returns, vehicle capacity usage, costs per delivery, average number of stops, driver idle time, and monthly vehicle maintenance costs. These KPIs provide a quantifiable way to assess performance, identify trends, and make informed decisions to enhance logistics operations.

4. Analyze Average Delivery Time

In this stage, businesses focus on metrics related to delivery efficiency, such as average delivery time, on-time delivery rate, perfect order rate, and picking accuracy. Analyzing these metrics helps organizations pinpoint areas that impact delivery performance, such as delays in order processing or inefficient routing. By identifying and addressing these issues, companies can improve their delivery times, ultimately enhancing customer satisfaction and loyalty.

5. Implement Customer Feedback

Integrating customer feedback into logistics operations is essential for creating a customer-centric approach. Organizations should prioritize understanding customer needs and expectations by putting the customer first in decision-making processes. This includes selecting the appropriate logistics model that meets customer requirements and providing real-time visibility into order status and delivery updates. By actively listening to customers and adapting logistics strategies accordingly, businesses can improve service quality and foster stronger customer relationships.

6. Set Up the Ideal Logistics Flow

Designing an optimized logistics flow is critical for ensuring smooth and efficient operations. This involves analyzing and optimizing various components of the logistics process, including storage, warehousing, materials handling, packaging, unitization, inventory management, and transportation logistics. Establishing an efficient logistics flow minimizes delays, reduces costs, and ensures that products move seamlessly through the supply chain. Incorporating information and control systems also enhances visibility and tracking throughout the logistics process.

7. Coordinate with Channel Partners

Effective coordination with channel partners—such as suppliers, distributors, and logistics service providers—is vital for successful logistics optimization. Collaborating closely with these partners helps align logistics strategies, share valuable data, and enhance communication across the supply chain. By fostering strong relationships and ensuring everyone is on the same page, organizations can improve overall efficiency, responsiveness, and service quality, leading to a more resilient supply chain.

7 Essential Diagrams for Effective Logistics Optimization

In logistics optimization, visual tools are invaluable for streamlining complex processes, enhancing decision-making, and uncovering improvement opportunities. Diagrams provide a clear, organized view of logistics workflows, from high-level supply chain management to specific processes like warehousing and transportation. The following seven diagrams are some of the most useful tools you can use to optimize logistics operations, reduce costs, and enhance efficiency.

1. Supply Chain Flowchart

Create a supply chain flowchart to map out each stage, from raw materials to final delivery. This diagram helps visualize the entire supply chain, making it easier to spot bottlenecks and inefficiencies that can delay deliveries or increase costs. It’s especially useful for planning and identifying areas where processes could be streamlined.

2. Logistics Process Flowchart

A logistics process flowchart details specific logistics activities like warehousing, inventory handling, and shipping. By mapping each step, this diagram allows you to see potential delays, redundant steps, or areas that need improvement, which is crucial for smoother and more efficient operations.

3. Transportation and Route Optimization Diagram

Use this diagram to outline and analyze transportation routes. By optimizing delivery paths and planning the most efficient routes, you can reduce fuel costs and shorten transit times, directly improving delivery performance and cutting operational expenses.

4. Warehouse Layout Diagram

This diagram provides a clear view of your warehouse layout, helping you design an efficient storage space. Use it to map out locations for high-frequency items, optimize picking paths, and arrange areas for packing and shipping. A well-organized warehouse layout reduces picking and packing times and ensures better space utilization.

5. Inventory Management Diagram

With an inventory management diagram, you can track stock levels, reorder points, and locations across different facilities. It’s useful for maintaining optimal stock levels, avoiding overstock and stockouts, and ensuring that stock is available when needed for order fulfillment.

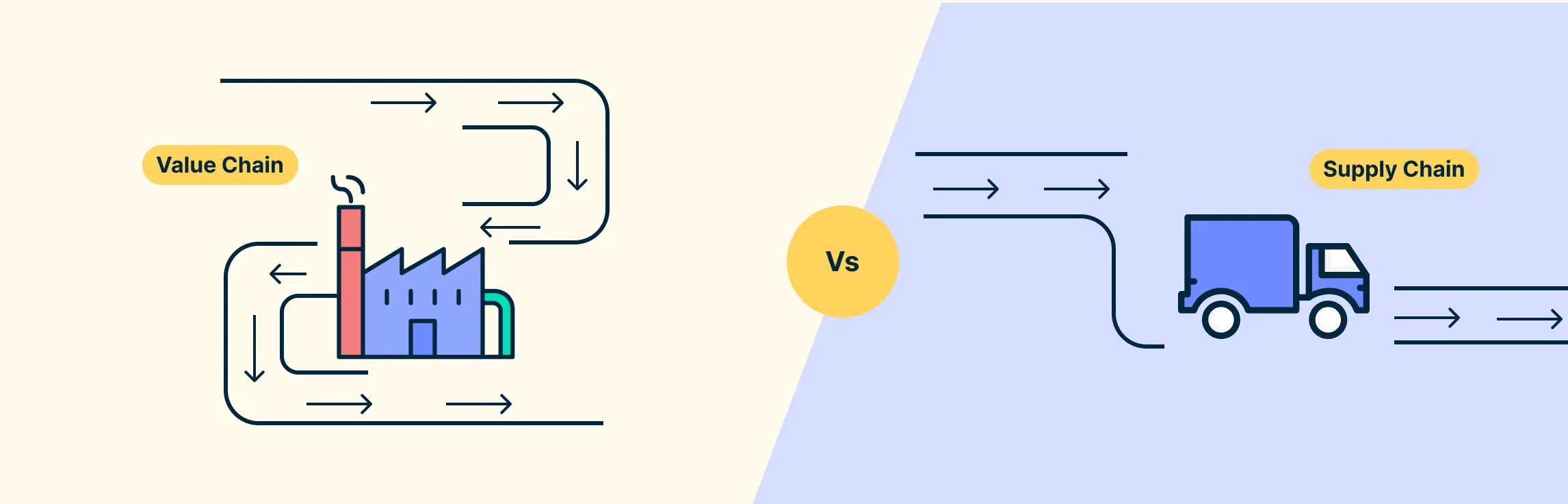

6. Value Stream Mapping (VSM)

Value Stream Mapping (VSM) is a powerful tool for visualizing the flow of materials and information across the entire supply chain. By creating a VSM, you can identify each step in the process, from raw material sourcing to product delivery. This diagram allows you to pinpoint areas of waste, such as excessive lead times, overproduction, and unnecessary handling.

7. Risk Management Diagram

A Risk Management Diagram identifies potential risks in the logistics process, such as delays and disruptions, and outlines contingency plans for each. Begin by brainstorming potential risks with your team and categorizing them based on their likelihood and impact. Once risks are mapped, develop specific contingency plans, including alternative suppliers or backup transportation methods, to mitigate their effects. Regularly review and update the diagram to ensure your logistics operations remain resilient and responsive to changing conditions, ultimately enhancing efficiency and customer satisfaction.

Helpful Resources

Use production & manufacturing planning software to visualize strategies for collaborative brainstorming, problem-solving, and so much more.

Create timelines for any event; track and analyze your team’s projects and tasks from start to finish with Creately’s Gantt chart maker.

Model your supply and demand data to anticipate future trends. Pinpoint inefficiencies and costs in processes on a single easily shareable workspace.

This operational planning tutorial will help you master the dynamic framework that adapts to challenges, aligns resources, and keeps everyone moving in the same direction.

Final Thoughts on Your Path to Effective Logistics Optimization

In conclusion, effective logistics optimization is a vital component of modern business strategy, enabling organizations to enhance efficiency, reduce costs, and improve customer satisfaction. We have explored the fundamental concepts of logistics optimization, its key benefits, and the structured stages necessary for successful implementation. The seven essential diagrams presented serve as practical tools to visualize and streamline your logistics processes, empowering you to make informed decisions that drive operational excellence. By embracing logistics optimization, businesses can not only meet the demands of today’s competitive landscape but also position themselves for sustained growth and success in the future. With the insights and strategies outlined in this guide, you are now equipped to unlock the full potential of your logistics operations and create a more efficient, responsive supply chain.

FAQs About Logistics Optimization

What is logistics optimization?

Why is logistics optimization important for businesses?

What are some common strategies for logistics optimization?

How can I measure the success of logistics optimization efforts?

What role do technology and data play in logistics optimization?

Resources:

Bartolacci, M.R., LeBlanc, L.J., Kayikci, Y. and Grossman, T.A. (2012). Optimization Modeling for Logistics: Options and Implementations. Journal of Business Logistics, 33(2), pp.118–127. doi:www.doi.org/10.1111/j.0000-0000.2012.01044.x.

Caunhye, A.M., Nie, X. and Pokharel, S. (2012). Optimization models in emergency logistics: A literature review. Socio-Economic Planning Sciences, 46(1), pp.4–13. doi:www.doi.org/10.1016/j.seps.2011.04.004.

Said, H. and El-Rayes, K. (2014). Automated multi-objective construction logistics optimization system. Automation in Construction, 43, pp.110–122. doi:www.doi.org/10.1016/j.autcon.2014.03.017.