Understanding Process Map vs Value Stream Map

Mapping is a critical component in business process management, directly influencing the efficiency and effectiveness of operations. Two frequently used mapping tools are the process map and the value stream map, each serving distinct purposes.

When comparing a process map vs value stream map, process maps visually detail every step within a workflow, aiming to enhance operational efficiency and productivity by identifying areas for improvement. In contrast, a value stream map offers a broader perspective, focusing on identifying and reducing waste to enhance end-to-end process optimization. Both tools provide significant insights into how processes can be refined to meet specific business needs.

Choosing the suitable mapping technique from process map vs value stream map directly aligns with an organization’s goals. Understanding the differences and strengths of process map vs value stream map allows businesses to select the most effective method for achieving and maintaining operational excellence.

What is a Process Map

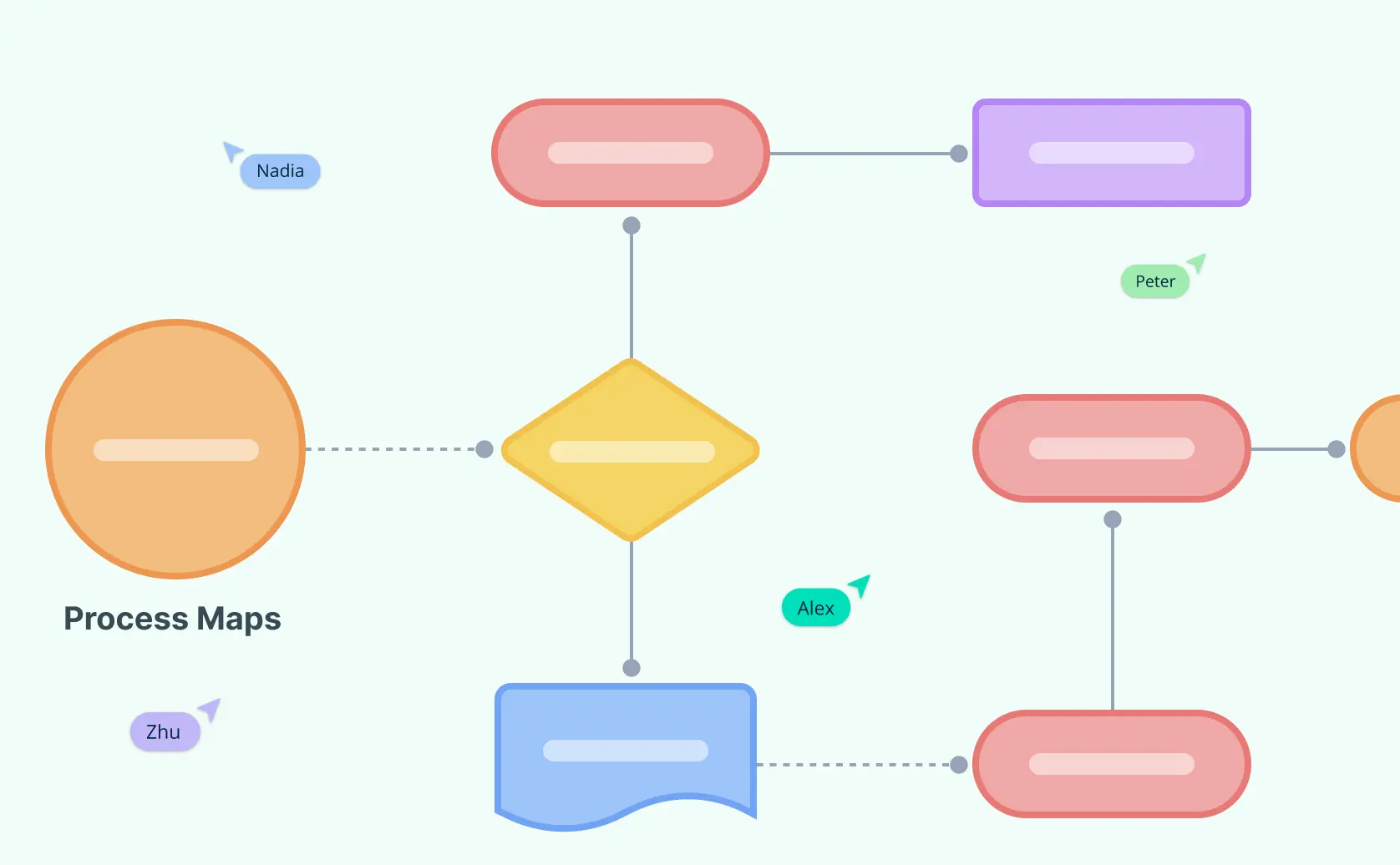

A process map is a visual tool that outlines the steps involved in completing a specific task or process, enabling a clear understanding of workflow and its components. Among the various types of process maps used in business process mapping, each serves to identify inefficiencies and opportunities for improvement within different workflows.

By employing process maps, organizations can effectively visualize and enhance workflow efficiency. This visual representation helps streamline processes by providing detailed insights into each step, ultimately facilitating smoother operations. Understanding the difference between a process map vs value stream map is essential, as both are integral to various industries such as manufacturing, healthcare, education, and information technology. Each map type plays a unique role in helping organizations optimize processes, which can significantly impact performance and productivity.

Benefits of Process Maps

Enhanced Communication: Process maps create a shared visual framework, making complex workflows easier to understand across teams and departments, which improves collaboration and alignment.

Efficiency Optimization: By pinpointing bottlenecks, redundant steps, and inefficiencies, process maps enable organizations to streamline operations, reduce wasted effort, and increase productivity.

Consistent Standards: Process maps provide a structured approach for training and execution, ensuring that teams follow consistent, standardized procedures and reducing variability in outcomes.

Comprehensive Documentation: Acting as a visual record of process workflows, process maps support compliance requirements and serve as reliable references during audits, quality checks, and process reviews.

Facilitates Continuous Improvement: With clear visibility into each process step, teams can continuously assess and refine workflows, making iterative improvements to adapt to changing business needs.

To create an effective process map, it’s crucial to clearly define the process name, detail each step through brainstorming, logically sequence these steps, and validate the flow with involved team members. Understanding the distinctions between a process map vs value stream map can further enhance this process, as each serves unique purposes in visualizing workflows. This approach ensures that process maps not only capture current workflows accurately but also highlight areas for continuous improvement, enabling businesses to optimize operations effectively.

What is a Value Stream Map?

Value stream mapping is a powerful visualization technique designed to highlight and eliminate waste, driving efficiency throughout an organization’s processes. Unlike conventional process maps that detail the procedural steps for improvement, value stream maps take a broader approach, focusing inherently on the value-added vs. non-value-added activities in a process.

This strategic tool is central to principles of lean management and methodologies like Six Sigma, providing a comprehensive overview of processes from a holistic vantage point. By pinpointing bottlenecks and redundancies, value stream maps empower companies to streamline operations, optimize resource usage, and ultimately enhance customer satisfaction.

Benefits of Value Stream Mapping

Identification and Reduction of Waste: Value stream maps allow organizations to pinpoint and quantify waste at each stage of a process. By clearly highlighting non-value-added activities, businesses can prioritize improvements and streamline operations to enhance efficiency.

Clarity in Complex Systems: By breaking down intricate processes into digestible steps, value stream maps—compared to process maps in the context of process map vs value stream map—make it easier for teams to understand and analyze workflows. This approach promotes clearer communication and alignment on improvement goals across departments, enhancing collaboration and efficiency in targeted process improvements.

Enhanced Lean Process Management: Focusing on the flow of value, value stream maps support lean management principles by identifying delays, redundancies, and inefficiencies. This results in optimized product or service delivery times, reduced costs, and improved resource allocation.

Data-Driven Decision Making: Value stream mapping provides actionable insights into current state processes, enabling data-backed decisions that help to set realistic, targeted goals for process improvement and better meet customer demands.

Cross-Functional Collaboration: By visually representing each part of a workflow, value stream maps facilitate collaboration across teams, as everyone gains a shared understanding of areas needing attention, driving cohesive efforts towards operational excellence.

In the context of process map vs value stream map, these maps are particularly effective in manufacturing settings where efficiency and waste reduction are top priorities. However, their application extends to sectors like healthcare, logistics, and service industries as well. The insights garnered from this mapping technique can significantly contribute to operational excellence and competitive advantage, making it an indispensable tool in the arsenal of lean practitioners.

Key Differences Between Process Maps and Value Stream Maps

When exploring business process mapping techniques, understanding the core differences between process map vs value stream map is essential. Each map serves distinct purposes and caters to varying business needs, making it crucial for organizations to choose the correct mapping tool for their objectives.

Firstly, the main focus of process maps is detailing every individual step within a process. They create a comprehensive breakdown that facilitates workflow efficiency improvements by identifying redundancies and bottlenecks in day-to-day operations. Conversely, value stream maps take a broader approach, targeting waste minimization and process reengineering. They provide a high-level view of the entire process flow from start to finish, highlighting where resources are consumed without adding value and suggesting opportunities for strategic improvement.

Here’s a table summarizing the key differences between process map vs value stream map:

| Aspect | Process Maps | Value Stream Maps |

| Purpose | Focuses on detailing each step within a specific workflow to improve operational efficiency. | Provides a high-level view to identify and reduce waste across the entire process for end-to-end optimization. |

| Scope | Narrower; often used to analyze individual tasks or smaller segments of a process. | Broader; examines the whole process from start to finish, including material and information flows. |

| Primary Focus | Workflow efficiency, identifying bottlenecks, and task-specific improvements. | Waste reduction, resource optimization, and enhancing value delivery across the process. |

| Use Cases | Used for training, documentation, compliance, and standardization of internal workflows. | Often applied in lean management, Six Sigma, and continuous improvement efforts for process reengineering. |

| Visualization | Uses detailed symbols to depict specific actions, decisions, and sequences within a process. | Visualizes both value-adding and non-value-adding steps, emphasizing where waste occurs. |

| Best For | Task-level improvements, such as refining specific steps in manufacturing or patient intake. | Process-wide enhancements, such as optimizing entire supply chains or production flows to increase efficiency. |

| Level of Detail | High level of detail on each individual step within the process. | Focuses on the overall process flow, often omitting minor steps to highlight major areas of waste. |

| Primary Users | Teams involved in operations, training, compliance, and workflow standardization. | Lean management teams, process engineers, and continuous improvement teams. |

| Examples | Streamlining employee onboarding steps, standardizing customer service protocols. | Reducing cycle time in manufacturing, minimizing delays in order fulfillment. |

| Outcome | Improved clarity and efficiency within specific workflows. | Comprehensive process optimization with reduced waste and improved customer satisfaction. |

Scenario-Based Examples:

- Process Maps: In a healthcare context, a process map may be used to streamline patient admission procedures, breaking down each step from the initial check-in to room assignment, ensuring quality and consistency in patient experience.

- Value Stream Maps: In manufacturing, a value stream map could be applied to optimize the production line, identifying stages where delays occur, aiming to reduce cycle times and improve throughput.

In comparing a process map vs value stream map, integrating both can lead to maximum efficiency, providing a comprehensive analysis that spans granular details and overall workflow enhancements. While process maps are essential for driving continuous improvements, value stream maps play a critical role in executing broader, transformative overhauls. This combined approach allows organizations to optimize daily operations and address larger systemic inefficiencies effectively.

Adopting Creately for your mapping needs can streamline this process, thanks to its robust features that support both process mapping and value stream mapping. Creately facilitates easy visualization and updates, fostering a collaborative environment for teams to innovate and optimize their workflows effectively.

Use Cases for Process Maps and Value Stream Maps

In the realm of business process mapping vs value stream mapping, acknowledging when to use each technique can significantly enhance operational efficiency. Here’s a detailed look at their applications:

Manufacturing Improvements: Process maps help streamline production by providing clear workflow visualizations, while value stream maps focus on identifying and eliminating waste to boost productivity.

Project Management: Utilize process maps to maintain visual project management, ensuring every task and phase is meticulously aligned. Meanwhile, value stream maps uncover inefficiencies, paving the way for quicker, more effective project deliveries.

Lean Management and Six Sigma: Both maps play crucial roles, with process maps aiding in the documentation and step-by-step enhancement of processes, and value stream maps focusing on waste reduction and process flow optimization.

Healthcare Operations: Process maps clarify patient care procedures, ensuring consistent and high-quality service, while value stream maps identify bottlenecks in patient flow, ultimately improving patient outcomes and reducing wait times.

These scenarios highlight how each mapping technique addresses unique challenges within business processes and provides strategic insights to choose the right approach.

Mapping business processes effectively is crucial for optimizing workflows and boosting team productivity. By using both a process map and a value stream map, organizations can harness the strengths of each mapping type. Understanding the difference between a process map vs value stream map enables organizations to implement targeted improvements and achieve more comprehensive, sustainable operational enhancements.

Integrating Process Maps and Value Stream Maps Together

When considering Business process map vs value stream map, integrating both can provide a more complete view of your operations. Here’s how they complement each other:

Business Process Maps:

- Focus on detailed task flows within a specific process.

- Help refine individual tasks, identifying inefficiencies at the task level.

- Ensure that each step in the process is optimized for efficiency.

Value Stream Maps:

- Provide a broader perspective by mapping the flow of value across departments or processes.

- Identify waste and bottlenecks that may be present across multiple processes.

- Focus on eliminating non-value-added activities across the entire value stream.

How They Work Together:

- Refine Daily Tasks: Use business process maps to optimize and refine tasks within a process.

- Eliminate Waste Across Departments: Leverage value stream maps to identify waste across departments or stages, ensuring a more holistic improvement.

- Comprehensive Process Improvement: Combining both maps provides a complete perspective—fine-tuning individual tasks with business process maps while addressing larger-scale inefficiencies with value stream maps.

By integrating business process map vs value stream map, organizations can achieve both detailed task-level optimization and strategic improvements across the entire value chain.

Using Process and Value Stream Maps for Continuous Improvement Programs

Integrating process map vs value stream map into improvement frameworks like Kaizen Method or TQM enhances sustainable growth. Process maps deliver detailed insights for continuous improvements, while value stream maps offer a high-level view to identify major inefficiencies. Together, they support comprehensive, ongoing optimizations in workflow and productivity.

Role of Business Process Maps:

Task-Level Refinement: Business process maps are ideal for identifying specific areas for improvement at the task or step level. These maps help teams pinpoint inefficiencies, bottlenecks, or redundancies within daily operations.

Iterative Updates: In continuous improvement, business process maps serve as living documents that are regularly reviewed and updated as new opportunities for enhancement arise.

Support for Kaizen: Kaizen focuses on small, incremental changes. Business process maps are essential for tracking these minor adjustments and ensuring they lead to tangible process improvements over time.

Role of Value Stream Maps:

Big-Picture Perspective: Value stream maps offer a broader view of how value flows across different departments or stages. They help identify non-value-added activities or waste that may not be visible in isolated process maps.

Strategic Optimization: By identifying bottlenecks and waste, value stream maps drive larger, systemic changes that align with TQM’s focus on overall quality and efficiency improvements.

Holistic Continuous Improvement: In frameworks like TQM, value stream maps help maintain focus on improving the entire value chain, ensuring that efforts are directed towards enhancing both customer satisfaction and operational efficiency.

Integration for Continuous Improvement:

Kaizen and Process Maps: Continuously update process maps as part of the Kaizen cycle to reflect iterative improvements and drive task-level efficiency.

TQM and Value Stream Maps: Use value stream maps to evaluate and eliminate waste across the organization, ensuring that strategic improvements are sustained in the long term.

Sustainability Through Mapping: Both business process maps and value stream maps support the ongoing identification and resolution of issues, keeping continuous improvement efforts aligned with business goals.

By integrating business process map vs value stream map within continuous improvement frameworks like Kaizen and TQM, organizations can create a culture of ongoing enhancement, ensuring sustainable growth and operational excellence.

Helpful Resources

Visualize, analyze, and improve organizational processes on a single, connected workspace.

Identify waste and inefficiencies in your existing processes and collaborate to develop solutions for improvement using our advanced value stream mapping software.

Use our powerful swimlane diagram maker to create business process diagrams online.

Using Creately for Process Map vs Value Stream Map

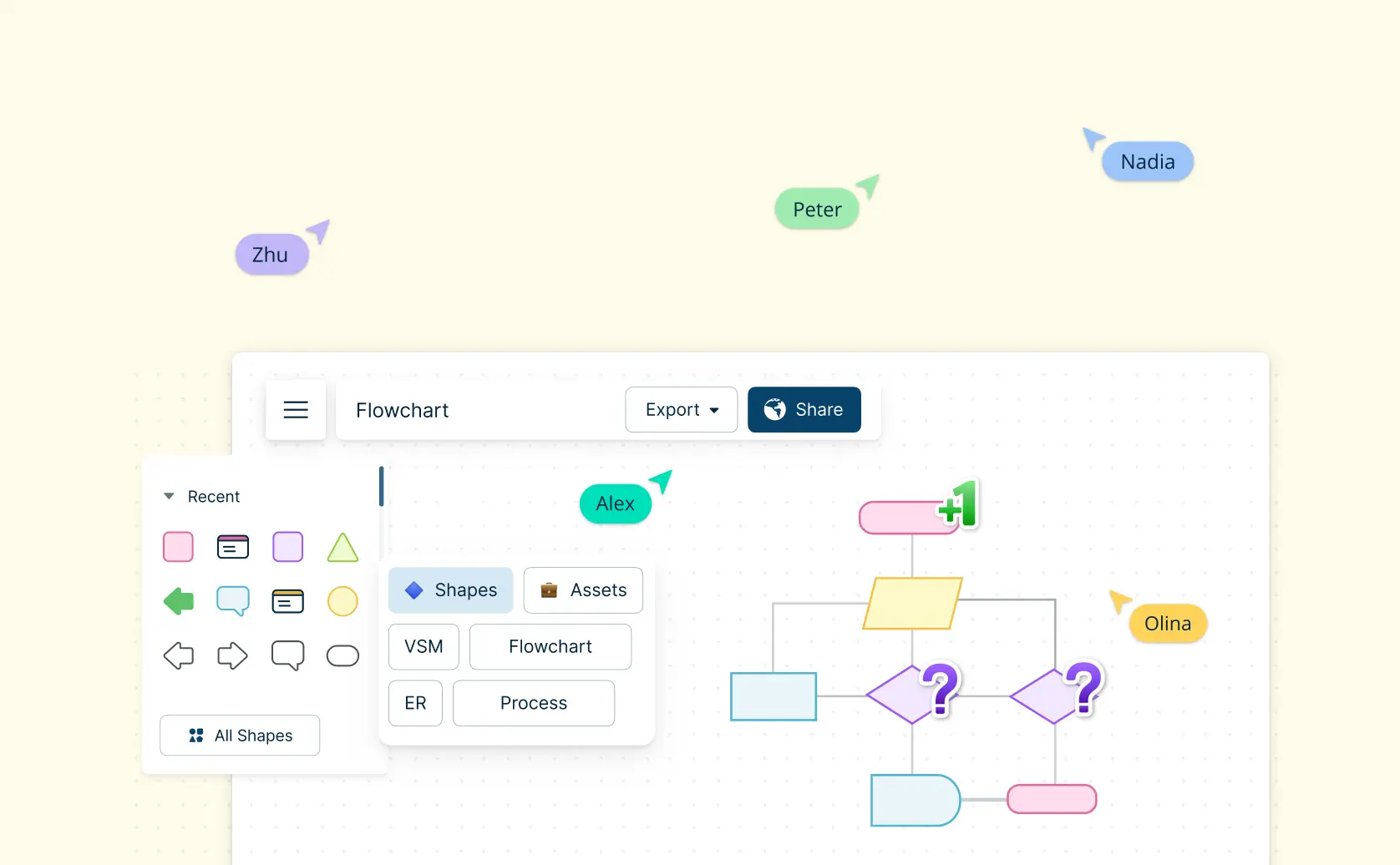

When it comes to effective business process management, Creately is a powerful tool for creating both process maps and value stream maps, enabling teams to optimize and visualize workflows across various functions. Whether you need a process map to detail every step within a workflow or a value stream map for broader end-to-end process analysis, Creately’s features are designed to make process map vs value stream map creation simpler and more efficient. Here’s a step-by-step guide to using Creately for both mapping techniques.

Step-by-Step Guide to Process Map vs Value Stream Map Creation with Creately

Access Creately: Start by logging into your Creately account, where the intuitive drag-and-drop interface allows for seamless creation of process maps and value stream maps. This user-friendly environment helps team members visualize workflows without technical complexity.

Select a Template: Creately offers a rich library of templates, ideal for both process map vs value stream map. Select a process map template if you want a step-by-step workflow representation or a value stream map template to capture the entire process flow, targeting waste and efficiency.

Define Your Process: Clearly define the process you wish to map. For process maps, focus on identifying every step within a workflow to enhance understanding. For value stream maps, include elements like material and information flow to identify waste points. Creately supports you in switching between process map vs value stream map based on your goals.

Customize Elements: Customize shapes, colors, and connectors in Creately to represent different stages and stakeholders in your process map or value stream map. This customization aids in enhancing clarity for both process map vs value stream map, ensuring accuracy.

Collaborate and Capture: Creately’s shared workspaces allow for real-time collaboration on process maps and value stream maps. Team members can comment, suggest, and refine, making the mapping process interactive and aligned with operational objectives.

Validate and Iterate: Ensure your process map vs value stream map are accurate by validating them with your team. Creately makes iterative refinement easy, enabling continuous improvements in both process mapping.

Advantages of Using Creately for Process Map vs Value Stream Map

Creately provides a feature-rich platform for creating process map vs value stream map, streamlining workflows and enhancing collaboration:

Creately’s Advanced Business Process Mapping Features

1. Automatic Database Creation: When users add elements to process maps, Creately automatically creates a centralized database that links data across all diagrams. Any change in one map reflects instantly across all related maps, promoting data integrity and making process reuse simple and efficient.

2. Modeling Capability: Creately’s centralized model storage ensures real-time updates are applied universally across all diagrams, reducing manual updates and enabling easy long-term scalability in process management.

3. Create Live Maps: Creately allows for “living” process maps that evolve as processes change. Continuous updates, version control, and collaborative review sessions keep diagrams accurate, aligned, and reflective of real-time business operations.

4. Collaboration and Reusability: Shared workspaces enable teams to collaborate on process maps in real-time. Processes can be reused across projects, keeping workflows consistent and reducing redundant work.

5. Customization and Data Integration: Creately provides extensive customization options for process maps, with integrated data fields and linking capabilities that make maps not only informative but also accessible and organized.

6. Automation Features: Automated tools for diagram generation and bulk updates minimize manual adjustments, speeding up process mapping for teams managing large or complex workflows.

7. Real-Time Updates and Iterations: Regular feedback and updates make it easy to refine process maps as new insights emerge, supporting continuous improvement in business operations.

8. Template Versatility: A variety of templates tailored to business process mapping ensures adherence to best practices and accelerates the mapping process.

9. Workflow Optimization and Strategic Visualization: Creately’s visual mapping tools help align process improvements with business goals, supporting incremental improvements and large-scale transformations for comprehensive workflow optimization.

Creately offers a versatile platform for modeling, automating, and optimizing business processes, combining advanced features like real-time collaboration, customization, and automation. Ideal for BPMN and value stream maps, it helps businesses streamline workflows and keep process maps aligned with evolving insights and goals.

Leveraging Templates for Process Map vs Value Stream Map

Using Creately’s templates specifically designed for process map vs value stream map can significantly speed up the mapping process. These templates provide a structural foundation that maintains clarity, coherence, and efficiency, supporting unique mapping needs.

For Process Maps: Templates help define task steps within a workflow, offering a visual aid that simplifies understanding. Process maps are especially valuable in manufacturing, healthcare, and education, where precise workflows are critical.

For Value Stream Maps: Templates for value stream maps highlight the broader aspects of process reengineering and waste reduction. They’re suitable for lean management practices such as Six Sigma, where the goal is to identify inefficiencies across a workflow.

Conclusion

Effectively mapping business processes is essential for optimizing workflows, reducing inefficiencies, and aligning operations with strategic goals. Process maps and value stream maps are two powerful tools for achieving these objectives, each offering unique advantages depending on whether the focus is on detailed step-by-step workflows or broader waste elimination. By understanding the strengths and applications of process map vs value stream map, organizations can make informed choices to enhance productivity and streamline processes.

Creately stands out as an invaluable tool for business process mapping, providing robust features that support the creation of both process maps and value stream maps. Its user-friendly interface, versatile templates, and collaborative environment enable teams to visualize, analyze, and improve processes with precision. For businesses aiming to enhance efficiency, improve cross-functional collaboration, and achieve continuous improvement, integrating Creately into their process mapping strategy is a strategic investment.

By leveraging process map vs value stream map in Creately, organizations gain a comprehensive approach to process management, fostering a culture of productivity and innovation that drives long-term success.

References

Al-Fedaghi, S. and Mohamad, Y. (2019). Business Process Mapping: A Case Study. 2019 IEEE/ACS 16th International Conference on Computer Systems and Applications (AICCSA). www.doi.org/10.1109/aiccsa47632.2019.9035277.