In business, it’s crucial to understand and meet customer demand to succeed. Demand management involves strategies to understand and shape what customers want. This guide explores its importance, basic principles, and strategies for businesses aiming to do well in today’s fast-changing market.

What is Demand Management?

Demand management is a critical component in the strategic alignment of supply with customer expectations. It involves a series of processes designed to manage and forecast customer demand to optimize the balance between supply and demand. This management process not only helps in reducing operational bottlenecks but also enhances organizational agility.

Within a business context, demand management refers to the systematic process of forecasting, planning, and controlling customer demand to maximize operational efficiency and customer satisfaction.

Managing Demand, Supply and Customer Expectations

Understanding demand management means looking at things like customer behavior, market trends, supply chains, the economy, and rules. This understanding helps predict demand, allocate resources, and make decisions, making it easier to adapt to changes in demand, manage inventory well, and take advantage of opportunities for growth.

Supply & Demand

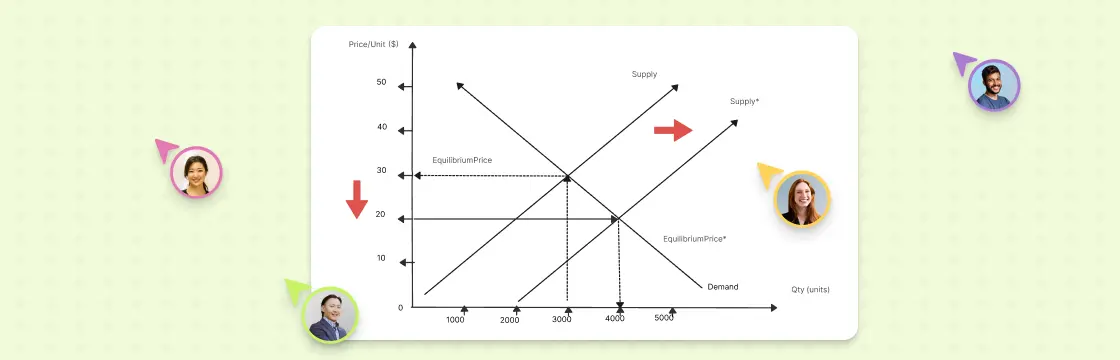

Supply and demand is a simple concept in economics. It’s about how much of something is available (supply) and how much people want it (demand). When there’s more supply than demand, prices go down. When there’s less supply than demand, prices go up. The balance between supply and demand determines the price and quantity of a product or service. When they’re equal, it’s called the equilibrium point. At this point, the market works efficiently, and neither buyers nor sellers have a reason to change their behavior. You can easily visualy the supply and demand with a supply & demand graph template.

Demand management focuses on the customer, aiming to predict and meet demand with the right products and services. Key areas of emphasis include better customer service, more accurate forecasting, and reduced costs.

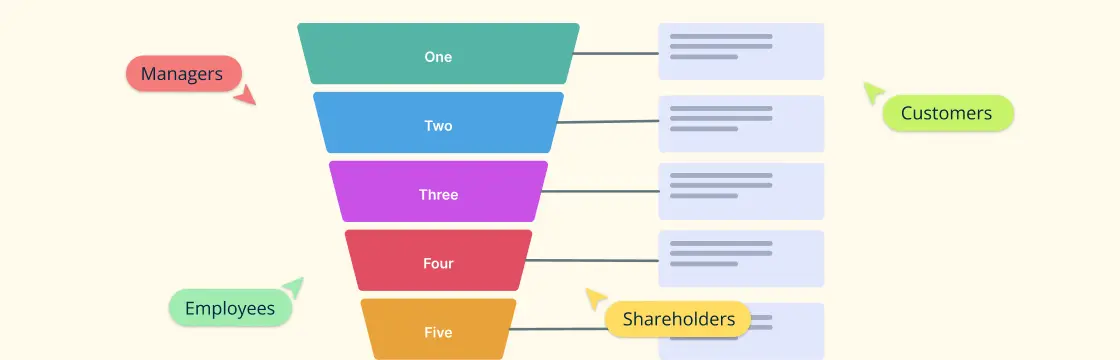

Specific objectives of customer-centric demand management include:

Improved customer service: Understanding customer needs and behaviors leads to higher satisfaction and better service. Demand management is crucial for businesses to meet customer needs without having too much or too little inventory, which keeps them competitive and keeps customers loyal. Accurate forecasting and managing customer demand help prevent disruptions in the supply chain and problems with operations.

Enhanced forecasting accuracy: Using predictive analytics helps make better decisions and improves supply chain management.

Cost reduction: Improved forecasting optimizes inventory investments and minimizes safety stock levels, saving money. Effective demand management helps you avoid excessive carrying costs, wasted product and the expense of last-minute orders, rush deliveries, refunds and extra staff. If you know what’s coming, you can stock and staff appropriately, maximizing your revenue.

- Product innovation: Develop new customer-appropriate products and refine them based on feedback for ongoing improvement.

- Efficient planning: Balance demand and supply to minimize surpluses using reliable data. Being agile, or quickly adjusting to changes in demand, is very important in fast-moving markets. Effective demand management helps with this, allowing businesses to succeed in changing environments.

The ultimate goals of demand management are increased sales growth and strong profit margins. It serves as a crucial decision support tool for business leaders, contributing to both strategic initiatives and day-to-day operations.

Key Differences: Demand Management VS Demand, Capacity & Supply Planning

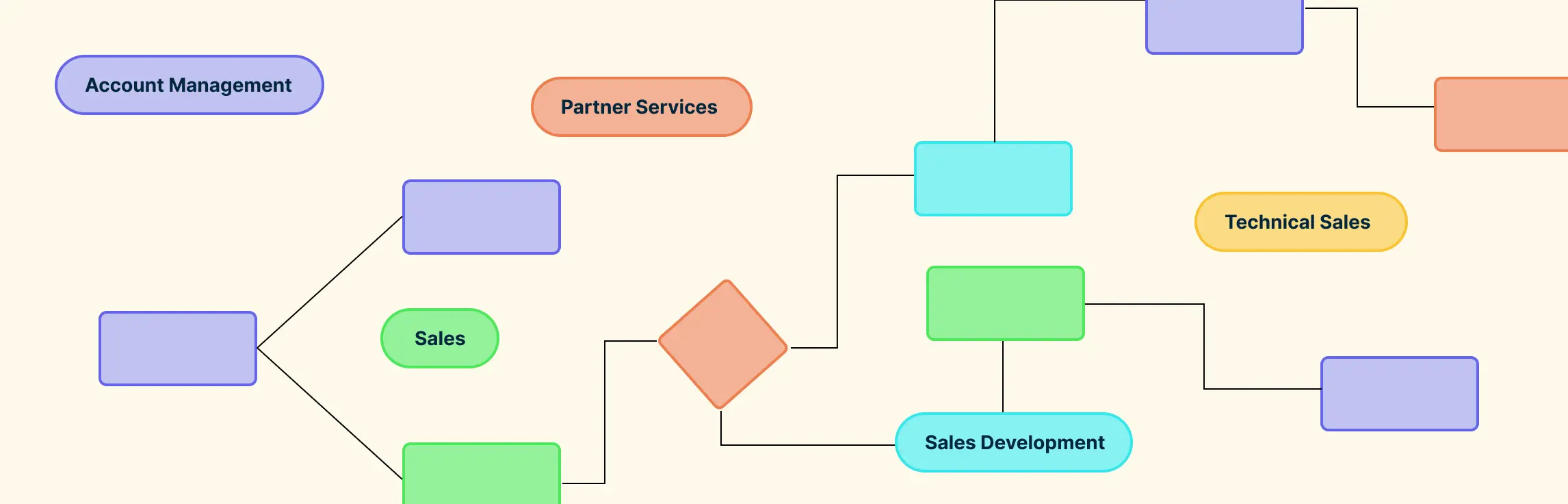

Understanding the factors between demand management, demand planning, and capacity planning is crucial for optimizing business operations. Each plays a distinct role in the broader scope of organizational efficiency and resource allocation. Demand management matches supply with demand, while demand planning predicts what customers will want. Capacity planning makes sure there are enough resources for operations.

Demand Management vs. Demand Planning

Demand management aligns what a business needs with what it can supply, thinking about both present and future needs to stay sustainable. Meanwhile, demand planning is more about predicting and meeting customer demand using past data and market analysis.

Demand Management vs. Capacity Planning

Demand management ensures efficient demand fulfillment, while capacity planning guarantees that the organization has enough resources to meet those demands. It’s all about optimizing resource allocation for operational excellence. Integrating demand management with capacity planning helps businesses meet current demands and scale operations effectively. A comprehensive guide to capacity planning. provides further insights into how these strategies can be effectively implemented.

Demand Management vs Supply Planning

Demand management predicts what customers will want. Supply planning figures out how to meet that demand without overspending or sacrificing service quality. It ensures your plans are realistic by considering production, inventory, and logistics.

By understanding these key differences and how they complement each other, businesses can better manage and plan their resources, leading to improved efficiency and reduced operational bottlenecks. For more detailed strategies on resource allocation, see 11 resource planning templates for smooth project execution.

Demand Management Examples Within Industries

Demand management involves predicting and fulfilling customer needs efficiently. It’s about using data to forecast how much of a product or service people will want and then making sure you can meet that demand without wasting resources. This applies across different industries, from retail to healthcare, where businesses adjust their plans and operations based on what customers are likely to want.

Retail: Predicting trends and adjusting inventory to avoid excess stock.

Manufacturing: Planning production and resources based on demand forecasts to reduce costs.

Hospitality: Adjusting prices and capacity to maximize revenue and occupancy rates.

Transportation: Optimizing shipping and logistics to reduce costs and transit times.

Healthcare: Allocating resources efficiently based on patient demand to enhance satisfaction.

Technology: Forecasting demand for products and adjusting offerings and strategies accordingly.

Energy: Balancing supply and demand to maintain stability and reduce costs with smart grid technologies.

5 Steps to Effective Demand Management

Effective demand management is crucial for matching business operations with market needs and customer expectations. By following these five steps closely, organizations can improve how they work and better respond to changes in the market.

Analyze Historical Data and Current Market: Start by analyzing historical data and studying current market trends, competitor actions, and economic signals to understand past performance and real-time conditions affecting demand. Visualize research data analysis using Creately.

Forecast Future Demand: Utilize data analysis and market research to predict future demand levels accurately based on the insights gained from historical data and current market analysis.

Develop Flexible Demand Strategies: Create flexible plans to handle expected demand by adjusting operations, marketing tactics, or product offerings as needed, considering both past data and current market conditions.

Integrate Demand Forecasts into Business Planning: Incorporate demand forecasts into overall business planning to align all departments towards common goals, optimizing resource usage and operational efficiency.

Coordinate Demand with Supply Planning and Process Optimization: Connect demand management with supply planning to ensure the supply chain can quickly adapt to changes in demand. Conclude the demand management cycle by evaluating and refining the process to establish the most effective system tailored to the business’s specific requirements. Map out your supply chain to garner deeper insights using effective supply chain management tools

Upon completion of the demand management lifecycle, it is important to initiate a new cycle with a focus on optimization. A thorough evaluation of how the demand management process can be refined to establish the most effective system tailored to the specific requirements of the business is needed. It is essential to acknowledge that the demand management process is dynamic and should adapt and evolve together with the evolving needs of the business.

Advantages of Demand Management

Advantages of demand management refer to the benefits or positive outcomes achieved through effectively forecasting, anticipating, and fulfilling customer demand for products or services. These advantages may include:

Right Inventory Levels: Demand management keeps inventory in line with what customers want, avoiding too much or too little stock.

Happier Customers: Meeting demand accurately makes customers happy, encouraging them to come back and spread positive feedback.

Efficiency Boost: Demand management streamlines production and resources, cutting waste and making operations smoother.

Saving Money: Avoiding excess inventory and supply chain issues saves money on storage, shipping, and holding costs.

Smarter Decisions: Insights from demand management help businesses plan production, buying, and resources better, leading to better overall decisions.

Adaptability: Businesses that manage demand well can quickly adjust to changes in the market and customer preferences, staying competitive.

Maximized Revenue: Matching production and stock with demand means businesses can make the most money by selling what customers want when they want it.

Stronger Supply Chain: Accurate forecasting and management keep the supply chain running smoothly, preventing disruptions and ensuring operations continue.

Good Reputation: Meeting demand consistently builds trust with customers, boosting the brand’s image and reputation. Read Creately’s guide on how to create a winning brand strategy to learn further.

Competitive Edge: Excelling in demand management gives businesses a leg up over rivals by anticipating trends, using resources efficiently, and providing great customer experiences.

Demand Management Challenges

Demand management comes with its fair share of challenges and difficulties that organizations face in effectively predicting, influencing, and fulfilling customer demand.

Forecasting Accuracy: Predicting future demand accurately is hard due to changing trends and customer preferences.

Data Quality and Availability: Reliable forecasts rely on accurate data, which may not always be available.

Supply Chain Complexity: Managing demand across multiple suppliers and locations can be complex.

Seasonality and Market Dynamics: Demand varies seasonally, and markets change rapidly.

Inventory Management: Balancing inventory levels is tricky to avoid overstocking or understocking. Read more on techniques to optimize inventory management.

Demand Volatility: Demand can be unpredictable, especially with changing consumer preferences.

Alignment with Business Goals: Ensuring demand strategies align with business objectives is crucial.

Resource Allocation: Allocating resources effectively to meet demand while controlling costs can be challenging.

Demand-Supply Mismatches: Mismatches between demand and supply can lead to issues like stock outs or excess inventory.

Technology and Tools: Implementing the right tools for forecasting and management can be complex and costly.

Addressing these challenges requires a combination of robust data analytics, effective communication across departments, strategic planning, and continuous improvement in demand management processes.

Difficulties of Demand Management

Difficulties of demand management refer to the potential drawbacks or challenges associated with forecasting, anticipating, and fulfilling customer demand for products or services. These may include:

Inventory Issues: Poor forecasting can cause too much or too little inventory, wasting money or missing sales opportunities.

Supply Chain Problems: Wrong predictions can disrupt production, supplier relationships, and upset customers.

Wasted Resources: Mismanagement can lead to inefficient production, causing unnecessary costs and reducing profits.

Higher Expenses: Bad demand management can increase costs for rush orders, shipping, and storage, cutting into profits.

Unhappy Customers: Inconsistent supply due to mismanagement can upset customers, harming the brand and loyalty. Explore Creately’s guide on improving customer service processes.

Missed Sales: Failing to meet demand means lost sales and losing out to competitors who do.

Complexity and Errors: Dealing with complicated factors like market trends and customer behavior can lead to mistakes in forecasting.

Resource Balancing Challenges: It’s hard to balance resources for fluctuating demand, leading to waste or shortages.

Lack of Adaptability: Being too rigid in managing demand can make it difficult to respond quickly to market changes, affecting competitiveness.

External Vulnerability: Demand management depends on outside factors like the economy and regulations, leaving the organization vulnerable to forces beyond its control.

Demand Management Best Practices

Managing demand better is really important for staying competitive and agile in today’s fast-moving markets. By always working to improve and using advanced technologies, businesses can work more efficiently and react faster to changes in the market.

Improve Forecasting Accuracy: Utilize advanced analytics and predictive modeling, incorporating real-time data for dynamic adjustments.

Ensure Data Quality: Invest in robust data management systems and validation processes to enhance accuracy and reliability.

Simplify Supply Chain: Streamline processes and foster collaboration with suppliers to improve visibility and coordination.

Adapt to Market Dynamics: Develop flexible strategies to adjust to seasonal variations and market shifts, monitoring trends closely.

Optimize Inventory: Use techniques like just-in-time inventory and tracking systems to minimize stockouts and excess inventory.

Address Demand Volatility: Implement agile planning processes and contingency plans to respond to unexpected demand fluctuations.

Align with Business Goals: Ensure demand objectives align with overall business goals, fostering cross-functional collaboration.

Optimize Resource Allocation: Implement tools and processes for efficient resource allocation, identifying areas for improvement.

Leverage Technology: Invest in advanced forecasting tools and provide training for effective utilization.

Listen to Customers: Incorporate customer feedback to refine strategies and predict future trends.

Adopt AI and Machine Learning: Implement AI and machine learning for predictive analysis and automation. Understand AI and explore possibilites in this comprehensive guide by Creately.

Maintain Flexibility: Stay agile to adapt quickly to changes in demand or supply chain issues.

Utilizing Creately for Demand Management

Demand management involves forecasting, planning, and controlling the demand for products or services to ensure that an organization meets its customers’ needs efficiently. Using Creately, you can create various visualizations and diagrams to help with demand management processes. Here’s how you can use Creately for demand management:

Demand Forecasting Diagrams: Create diagrams illustrating the demand forecasting process. This might include techniques like time series analysis, regression analysis, or qualitative methods. Use Creately’s diagramming tools, shape libraries and templates to represent these techniques visually, making it easier to understand for stakeholders.

Supply and Demand Graphs: Visualize supply and demand curves to understand market equilibrium and fluctuations in demand. Creately provides tools to draw graphs easily, allowing you to analyze how changes in factors such as price, consumer preferences, or external influences affect demand.

Inventory Management Flowcharts: Design flowcharts showing inventory management processes, including ordering, storage, and distribution. Creately’s templates and shapes can help you map out these processes step by step, identifying potential bottlenecks and areas for improvement. Explore creately’s inventory management templates.

Capacity Planning Diagrams: Use Creately to create capacity planning diagrams, illustrating how demand fluctuates over time and how resources are allocated to meet that demand. This can include workforce planning, production scheduling, and resource allocation strategies.

Scenario Planning Maps: Develop scenario planning maps to anticipate and prepare for different demand scenarios, such as seasonal fluctuations or changes in consumer behavior. Creately allows you to create multiple scenarios and compare their potential impacts on demand and operations.

Collaborative Planning Boards: Utilize Creately’s real-time collaboration features to engage stakeholders in demand planning sessions. Create planning boards where team members can contribute ideas, identify risks, and propose strategies to manage demand effectively.

Dashboard Visualization: Create interactive dashboards using Creately’s features to monitor key demand metrics in real-time. Creately’s tools have the ability to bring data on to the canvas and give them structure for better analysis. Dashboards can include charts, graphs, and KPIs that provide insights into demand patterns, customer preferences, and market trends.

Conclusion

Demand management is important for matching supply with what customers want, making operations run smoothly and keeping customers happy. It involves predicting, planning, and controlling customer demand to balance supply and demand, reducing problems and making the business more flexible. In changing economic times, things like how people buy and market trends affect demand a lot, so it’s important to forecast accurately and make smart decisions. Demand management is different from demand planning and capacity planning because it focuses on strategic planning, forecasting, and using resources wisely.

To improve efficiency and react faster, businesses should look at past data, study the market, predict future demand, and use those predictions to plan their business and supply better. To make demand management better, it’s important to always be looking for ways to improve, use data to make better decisions, listen to customers, and use new technology. This helps businesses stay competitive and flexible.