A distribution network connects manufacturers to consumers, optimizing storage and transportation for efficient and cost-effective delivery. By enhancing operational efficiency, scalability, and team collaboration, a well-designed network ensures timely delivery and reduces costs. This guide highlights strategies to boost logistics efficiency and teamwork, leveraging technologies like AI to transform operations.

What Is a Distribution Network?

A distribution network is a dynamic system that ensures the smooth movement of products from manufacturers to customers through various distribution channels. Key components of an effective distribution network include central and outlying warehouses. Central warehouses help reduce inventory costs by serving as collection and distribution hubs, while outlying warehouses speed up deliveries by being strategically located near end users. This arrangement enhances delivery speed and overall efficiency across different distribution channels.

Modern logistics technology, including artificial intelligence and automation, helps businesses predict demand, optimize logistics, and improve sustainability. Efficient inventory management and order processing are key to fast fulfillment and customer satisfaction, while addressing challenges in these areas can further enhance the distribution network to meet evolving demands.

Centralized vs. Decentralized Distribution Networks

What is a Centralized Distribution Network?

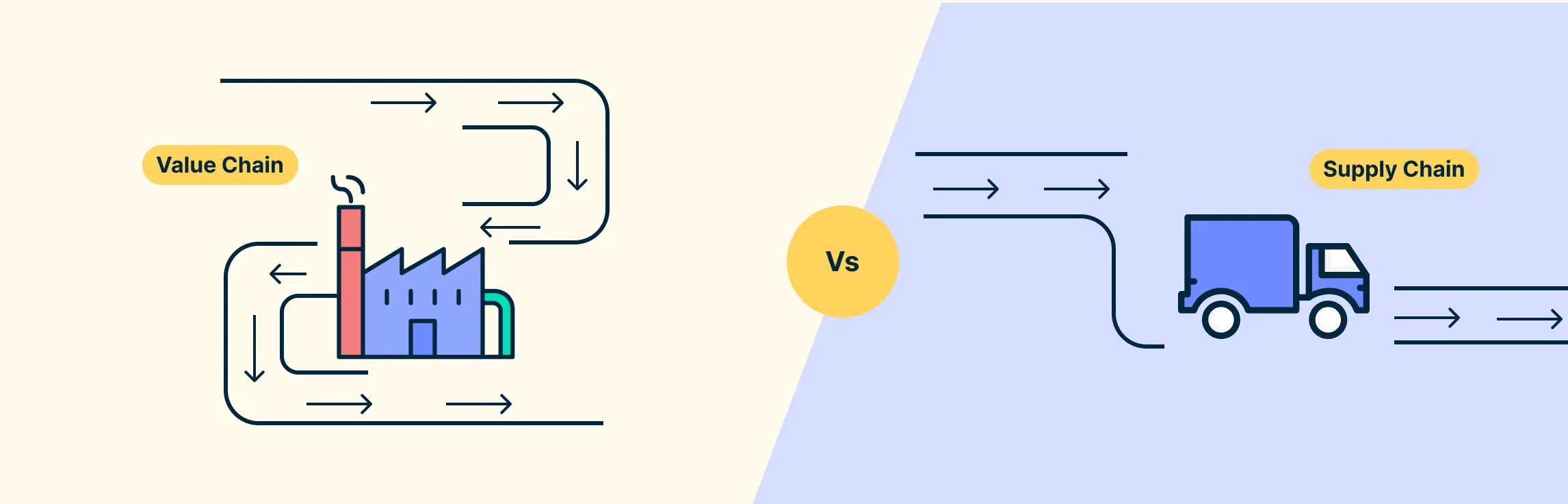

Centralized networks rely on a single hub for product distribution. This model prioritizes cost efficiency and centralized distribution managementfd, making it ideal for consolidating operations, reducing overheads, and maintaining control over inventory and order processing. However, it can lead to longer delivery times for distant regions, making it less agile in meeting local demand.

What is a Decentralized Distribution Network?

Decentralized networks use multiple distribution centers located closer to customers. This model prioritizes faster delivery times and better responsiveness to local demand. By being closer to end-users, decentralized networks offer greater agility and customer satisfaction. However, the model often results in higher operational costs due to the need for multiple facilities and increased complexity in inventory management.

This table compares centralized and decentralized distribution networks, outlining key differences:

| Aspect | Centralized Distribution Network | Decentralized Distribution Network |

|---|---|---|

| Primary Focus | Cost efficiency and centralized control | Agility and responsiveness to local demand |

| Infrastructure | Single hub | Multiple distribution centers |

| Delivery Time | Longer for distant regions | Faster, as distribution centers are closer to customers |

| Inventory Management | Easier to control and optimize | More complex due to multiple locations |

| Operational Costs | Lower overheads and economies of scale | Higher due to multiple facilities |

| Customer Satisfaction | May decrease in remote areas due to slower delivery | Higher due to faster delivery and better local responsiveness |

| Scalability | Easier to scale in a controlled environment | May require significant resources to scale effectively |

| Ideal For | Businesses prioritizing cost efficiency and control | Businesses prioritizing speed, flexibility, and local demand |

Usually decentralized networks use multiple smaller hubs, each functioning like a central hub. This model excels at speeding up delivery times and responding quickly to local demand. It’s particularly beneficial for markets with diverse customer needs, improving customer satisfaction by enabling faster and more frequent shipments.

Organizations must find a balance between cost-efficiency and delivery speed when choosing the most suitable model for their business. Using tools like Creately’s Supply Chain Management can help visualize and map out these networks, offering data-driven insights and clear representations of distribution strategies. This enables supply chain managers to optimize procurement strategies and inventory management practices.

Building the Ideal Distribution Network or Model

Creating an ideal distribution network or model involves a careful balance between cost, delivery speed, inventory control, and the ability to adapt to changing customer demands. To design an effective network, businesses must consider several key factors:

1. Business Objectives:

Define the primary goals of the network. Is the focus on reducing costs, improving delivery speed, or maintaining tight inventory control? Understanding the business’s needs helps shape the network model.

2. Customer Location and Demand Patterns:

Mapping out where customers are located and their demand behaviors is critical. A centralized model might work well for regions with lower customer density, while a decentralized approach may be better for areas with high demand or regional variations.

3. Technology and Automation:

Leverage technology, such as AI and automation, to optimize processes. These technologies can predict demand, streamline operations, and improve supply chain visibility, making the distribution network more agile and efficient.

4. Supply Chain Agility:

Flexibility is crucial in adapting to market changes, seasonal demand spikes, and unforeseen disruptions. Decentralized networks often provide greater agility by allowing businesses to respond quickly to local demand fluctuations.

5. Cost Analysis:

Conduct a detailed cost-benefit analysis to determine the optimal network structure. While a centralized model may lower overhead costs, a decentralized model can improve delivery speed, resulting in higher customer satisfaction and potentially greater revenue in the long term.

6. Environmental and Sustainability Goals:

Incorporating sustainability into the distribution network design can help reduce carbon footprints. Smarter routing and warehouse optimization can contribute to more eco-friendly logistics operations.

Using visualization tools like Creately’s logistics design frameworks helps map out potential distribution strategies, offering clear, actionable insights for decision-makers. These tools aid in visualizing complex supply chain networks, optimizing routes, and refining processes to create the most efficient and cost-effective distribution model.

7 Benefits of a Distribution Network

The benefits of a distribution network are vast and critical for businesses aiming to optimize their logistics and supply chain operations. Here are some key benefits:

1. Enhanced Efficiency

Streamlines the movement of goods, reducing delays and operational costs while improving delivery speed.

2. Cost Savings

Consolidates resources like warehouses and transportation, lowering overhead and shipping expenses.

3. Improved Customer Satisfaction

Faster, reliable deliveries lead to higher customer satisfaction and retention.

4. Flexibility and Scalability

Adapts to market changes, allowing businesses to grow and meet rising demand.

5. Better Inventory Management

Optimizes stock levels and reduces costs by strategically positioning warehouses.

6. Global Reach

Expands businesses globally, ensuring timely delivery to international markets.

7. Data-Driven Insights

Uses modern technology to provide valuable logistics data that aids in optimizing future strategies.

A strong distribution network drives efficiency, boosts customer experience, and supports growth.

Key Challenges in Designing Distribution Networks

Designing an efficient distribution network involves navigating several challenges that can significantly impact logistics performance and customer satisfaction. Below are the key obstacles businesses face:

- Cost vs. Speed

- Balancing cost-efficiency with fast delivery is a common challenge. Centralized networks cut costs but slow delivery, while decentralized ones improve speed but raise costs.

- Demand Forecasting

- Predicting customer demand accurately is difficult due to seasonal changes and market uncertainties.

- Warehouse Locations

- Poorly placed warehouses increase transportation costs and delivery times.

- Technology Integration

- Adopting AI and automation can be costly and time-consuming. Resistance to change may slow adoption.

- Supply Chain Disruptions

- External factors like disasters or geopolitical issues disrupt operations.

- Sustainability

- Pressure to adopt eco-friendly practices adds complexity and costs.

- Channel Complexity

- Managing inventory and schedules across multiple regions and product lines can be overwhelming.

Overcoming these challenges requires a strategic approach, leveraging technology, and aligning operations to meet customer demands efficiently.

Best Practices for Managing Distribution Networks

Effective distribution network management requires strategic planning and the adoption of practices that enhance operational efficiency. Here are some best practices to consider:

- Data-Driven Decisions

- Use analytics to optimize inventory, routes, and costs.

- Advanced Technology

- Implement AI for demand forecasting and automation for efficiency.

- Regular Audits

- Identify inefficiencies by reviewing warehouse and transportation performance.

- Strategic Warehouse Placement

- Place warehouses for optimal delivery times and cost efficiency.

- Flexibility & Scalability

- Adapt to market changes with a scalable, decentralized approach.

- Sustainability

- Optimize routes, use energy-efficient operations, and reduce waste.

- Collaboration

- Use real-time tools like Creately to improve team coordination.

- Employee Training

- Train teams to handle advanced tools and manage disruptions.

- Contingency Planning

- Prepare for disruptions with backup routes and diversified suppliers.

- Customer-Centric Focus

- Align operations to ensure fast delivery, flexible shipping, and accurate tracking.

By implementing these practices, businesses can streamline their distribution processes, reduce costs, and deliver exceptional customer experiences.

Leveraging Technology for Smarter and More Efficient Distribution Networks

In the rapidly evolving landscape of distribution networks, technology plays a pivotal role in boosting efficiency and meeting customer demands seamlessly. Implementing technological advancements like Artificial Intelligence (AI) and automation has revolutionized how logistics operate, allowing businesses to stay competitive in a global market.

- AI in Logistics: AI optimizes logistics by forecasting demand, managing inventory, and planning routes. It reduces errors, minimizes waste, and cuts logistics costs, resulting in more precise operations and better customer satisfaction.

- Automation in Warehousing: Automation accelerates order processing and inventory management. Robotics and automated systems in warehouses boost efficiency, reduce errors, and enable faster deliveries, improving customer retention.

- Integrated Technology Solutions: These solutions streamline operations by enabling real-time data sharing and decision-making. This ensures teams can respond quickly to market changes and optimize distribution strategies.

- Sustainable Innovations in Logistics: Focus on energy-efficient routing and resource optimization reduces the carbon footprint of logistics operations. These eco-friendly practices appeal to consumers and help businesses meet environmental goals.

Technology is transforming distribution networks, making them more efficient and responsive. AI optimizes logistics by predicting demand and managing inventory, while automation speeds up order processing and warehouse operations. Integrated solutions enable real-time data sharing, improving decision-making, and sustainable practices help reduce the environmental impact of logistics. Together, these technologies enhance operational efficiency, customer satisfaction, and sustainability, helping businesses stay competitive.

Utilizing Creately for Distribution Network Management

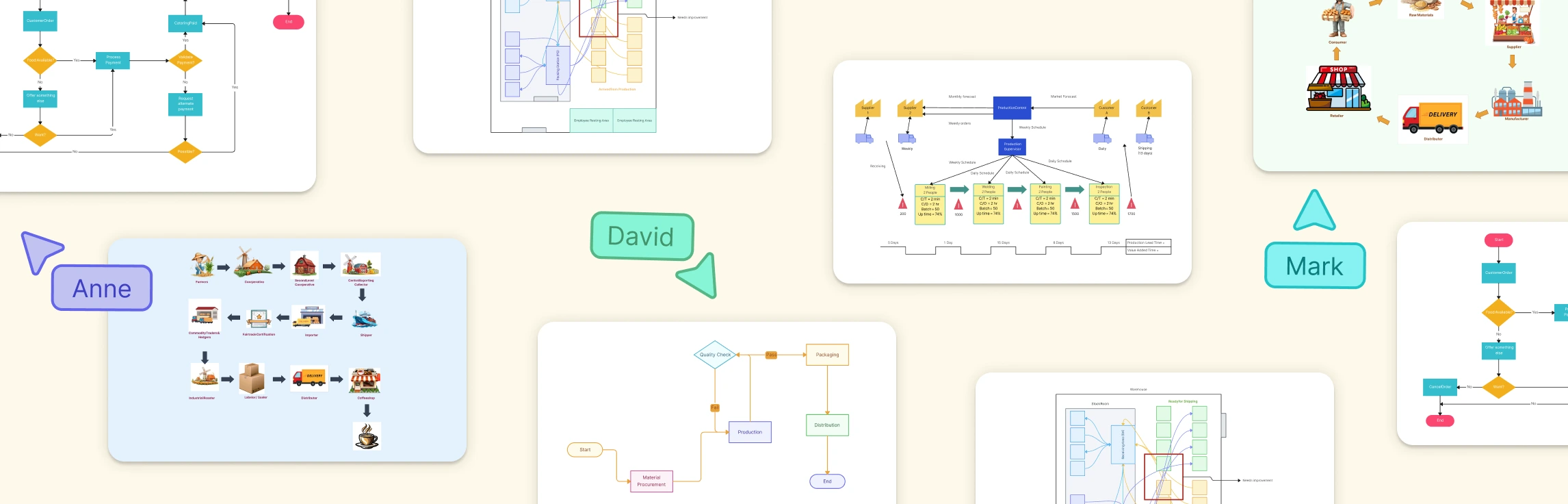

Creately can significantly enhance (distribution management)(https://creately.com/guides/distribution-management/) by offering powerful tools to design, plan, and optimize distribution networks. With its intuitive visual workspace, Creately enables businesses to map out and visualize complex distribution strategies, ensuring better clarity and decision-making. Here’s how Creately can assist in distribution management:

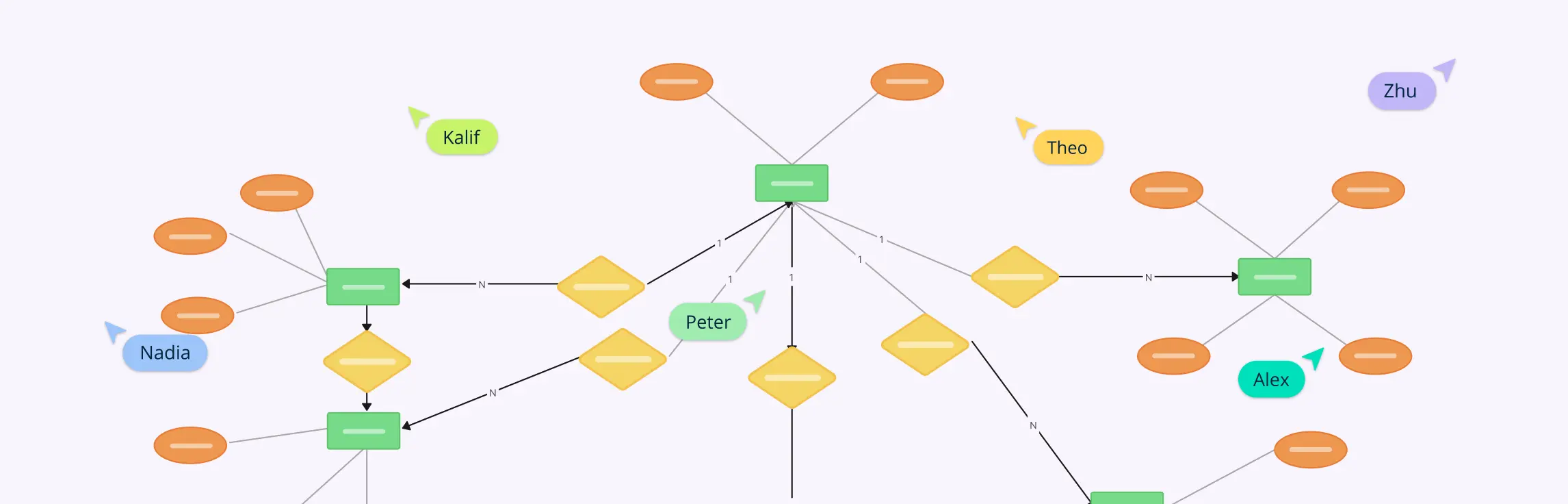

Streamlined Collaboration for Distribution Network Planning: Creately’s real-time collaboration tools enable teams to plan and optimize distribution networks by mapping strategies visually, identifying key hubs and bottlenecks, and refining plans with live updates and feedback. This ensures efficient and well-optimized distribution workflows.

Customizable AI-Enhanced Distribution Network Templates: Access a library of AI-enhanced templates tailored for designing distribution networks in areas like inventory management, central and outlying warehouses, and transportation routes. Quickly start with pre-built templates that are fully customizable, ensuring visually appealing and logically structured distribution network designs for any business scenario.

Visualizing Distribution Networks: Creately helps create detailed diagrams of distribution channels, including central and outlying warehouses, transportation routes, and inventory management processes. This visual representation provides teams with a clear understanding of their logistics operations.

Optimizing Workflow: Creately’s features assist in streamlining the workflow, allowing businesses to identify potential bottlenecks and optimize processes such as order processing, inventory management, and delivery routing.

Data-Driven Insights: By integrating data into diagrams, Creately empowers businesses to analyze logistics performance, uncover trends, and make informed decisions to improve operational efficiency.

By utilizing Creately’s visual tools, businesses can better manage, optimize, and scale their distribution networks, improving both operational efficiency and customer satisfaction.

Conclusion

A distribution network is crucial for ensuring efficient product movement from manufacturers to customers. Businesses must choose between centralized and decentralized models based on factors like cost, delivery speed, and customer demand. Technological advancements such as AI, automation, and integrated solutions play a key role in optimizing logistics, improving efficiency, and reducing costs.

Creately offers powerful tools to help businesses design, visualize, and optimize distribution networks, ensuring better inventory management, faster deliveries, and improved customer satisfaction. By leveraging these tools, businesses can enhance operational efficiency, scalability, and sustainability, ensuring long-term success in a competitive market.

Resources:

Supply Chain 24/7 (2020) The role of distribution networks in supply chain optimization. Available at: https://www.supplychain247.com/article/role_of_distribution_networks_in_supply_chain_optimization

Deloitte (2020) Distribution networks in the digital age. Deloitte Insights. Available at: https://www2.deloitte.com/global/en/insights/industry/retail-distribution-networks.html

Gudehus, T. (2016) ‘Optimization of distribution networks’, Proceedings of the 10th International Conference on Logistics and Supply Chain Management, 1-3 May 2016, Berlin. Available at: https://www.springer.com/gde/logistics-distribution-networks

FAQs on Distribution Network

What is a distribution network?

What are the key components of a distribution network?

How does a distribution network differ from distribution channels?

Why is a distribution network important for a business?