Problems are a part of life—whether they pop up at work, at home, or in unexpected places. But solving them effectively often comes down to understanding their root cause. That’s where tools like the 5 Whys come in handy.

In this guide, we’ll walk you through everything you need to know about the 5 Whys technique. From what it is and how it works to practical tips and real-life examples, you’ll learn how to use this simple but powerful method to uncover the true source of problems and create meaningful solutions.

What Is 5 Whys Analysis

The 5 Whys analysis is a simple, structured method for finding the root cause of a problem. At its core, it involves asking “Why?” repeatedly—usually five times—to dig deeper into the issue until you uncover its true source. This isn’t about assigning blame but understanding what’s really causing the problem so you can fix it effectively.

The idea is straightforward: every problem has a deeper cause, and by peeling back the layers one “Why?” at a time, you can trace the issue to its origin. For example, if a car won’t start, asking “Why?” might look like this:

- Why won’t the car start? → The battery is dead.

- Why is the battery dead? → The alternator isn’t working.

- Why isn’t the alternator working? → The alternator belt is broken.

- Why is the belt broken? → It wasn’t replaced on time.

- Why wasn’t it replaced? → There was no maintenance schedule in place.

In this example, the root cause isn’t just the dead battery—it’s the lack of a maintenance schedule. Fixing the battery solves the immediate problem, but addressing the root cause prevents it from happening again.

Why the 5 whys technique matters

Problems often show up as symptoms. You might think you’re solving the issue when you treat the symptom, but without understanding the root cause, the problem can reappear in different forms. The 5 Whys technique is like detective work—it helps you see beyond the obvious and solve problems at their source.

This method is especially valued for its simplicity. You don’t need special tools or deep technical knowledge; you just need a clear problem and a willingness to ask questions thoughtfully. It’s used across industries—from manufacturing and healthcare to business and personal development—because it’s flexible and effective.

Key principles of 5 Whys analysis

- Focus on the process, not people: The goal is to find what went wrong, not who to blame. Problems often stem from systems, processes, or gaps in planning.

- Keep it simple: You don’t need to overcomplicate things. The 5 Whys is a straightforward process anyone can follow.

- Be persistent but open-minded: Five is just a guideline. You might find the root cause in three Whys or need seven. The point is to keep asking until the problem is fully understood.

- Document the process: Writing down each step helps clarify your thinking and ensures everyone on the team is on the same page.

How to Conduct a 5 Whys Analysis

The 5 Whys analysis is straightforward, but doing it effectively requires a clear process. Follow these steps to ensure you get to the root cause of the problem and create meaningful solutions.

Step 1. Clearly define the problem

Start by describing the problem in a way that’s specific and easy to understand. Avoid vague or broad statements like “Everything is behind schedule.” Instead, focus on the exact issue you want to analyze. For example:

- Instead of saying, “Our project is delayed,” you could say, “The final report for the project was not submitted by the deadline.”

- Or instead of saying, “The system isn’t working,” you could say, “The online checkout process is failing for 20% of users.”

Why is this important? A clear problem statement makes it easier to focus on the real issue. It keeps everyone on the same page and sets the stage for asking meaningful “Why?” questions.

Step 2. Assemble the right team

Once you’ve defined the problem, the next step is to bring together the right people to help analyze it. Why? Because the people closest to the issue often have the best insights into what caused it.

A good team includes individuals who understand the process or area where the problem happened. They’ve seen what works and what doesn’t, so they can help identify the root cause more effectively.

Here’s how to assemble the right team:

- Involve people with firsthand experience: Choose team members who were directly involved with the problem. They can provide valuable details about what went wrong.

- Add different perspectives: Include individuals from related areas or departments. A fresh perspective can uncover things others might overlook.

- Keep the group balanced: The team should be big enough to cover all the angles but small enough to stay focused. A group of 3–7 people is usually ideal.

Step 3. Ask “Why?” and record the answers

Now it’s time to get to the heart of the problem by asking, “Why?” Start with the problem statement and keep digging deeper with each answer you get. This step is all about exploring the cause-and-effect chain to uncover the root cause.

How to ask “Why?”

Begin with the problem statement: For example: “The project report was not submitted on time.”

Ask “Why did this happen?” Answer: “The draft wasn’t completed.”

Ask “Why?” again based on that answer:

- “Why wasn’t the draft completed?”

- Answer: “Key data wasn’t collected in time.”

Continue asking “Why?” until you reach the root cause:

- “Why wasn’t the data collected in time?” → “No one was assigned to collect it.”

- “Why wasn’t anyone assigned?” → “There was no clear responsibility outlined in the project plan.”

Each “Why?” digs deeper, uncovering what really caused the issue. You may not always need exactly five questions—it could take more or fewer to get to the root cause. The key is to keep going until you’re satisfied that the real problem has been identified.

Step 4. Stop when you reach the root cause

Now that you’ve been asking “Why?” and digging deeper, it’s important to know when to stop. The goal isn’t to ask “Why?” five times exactly—it’s to keep going until you reach the real, underlying cause of the problem.

How to know when you’ve reached the root cause:

- The answers no longer lead to another “Why?”

If your answer doesn’t have a clear cause behind it, it might be the root cause. For example:

- Why wasn’t the data collected on time? → “There was no clear responsibility assigned.”

- You can’t really ask, “Why wasn’t responsibility assigned?” in this case, because the issue is that the responsibility simply wasn’t defined.

- The cause points to something that can be fixed

Once you’ve identified a cause that’s actionable (something you can change or improve), you’ve likely reached the root cause.

- For example, “No one was assigned to collect the data” points to a clear solution—assigning responsibility in the project plan.

Step 5. Develop and implement a solution

Once you’ve identified the root cause, the next step is to come up with a solution that fixes the problem at its core. This is where you turn your insights into action.

How to develop a solution:

- Brainstorm solutions: Work with your team to come up with ideas that can solve the root cause. Focus on solutions that prevent the problem from happening again.

- Example: If the root cause is “No one was assigned to collect the data,” the solution could be to assign specific team members to handle data collection and set clear deadlines.

- Evaluate your options: Look at your proposed solutions and decide which one will work best. Consider factors like time, resources, and the impact of the solution.

- Example: A quick solution might be to assign someone to collect the data immediately, but a more long-term solution could be adjusting your process to include a responsible person for data collection in future projects.

- Create an action plan: Once you’ve chosen the best solution, write a clear action plan that outlines who will do what, by when. This makes it easier to follow through and ensures everyone is on the same page.

- Example: “Assign John as the data collector for this project and update the project plan to include a data collection step for future projects.”

How to implement the solution:

- Communicate the plan: Share the solution and action plan with everyone involved. Make sure everyone knows their role in making the solution work.

- Example: Inform the team that John will handle data collection and ensure they update the project plan accordingly.

- Follow through: Implement the solution by making the necessary changes and ensuring that everyone sticks to the action plan. Keep track of progress and be ready to make adjustments if needed.

- Example: After assigning the responsibility, monitor how well the data collection process is working and make sure it’s happening on time.

5 Whys Templates

Streamline your problem-solving process with customizable 5 Whys templates. These ready-to-use designs help you quickly identify root causes and document your findings effectively.

5 Whys Analysis Template

5 Whys Analysis Template for Design Thinking

5 Whys Analysis Template for DMAIC

Basic 5 Whys Analysis Template

5 Whys Analysis

5 Whys Analysis Example

5 Reasons for DMAIC

The Origin of the 5 Whys Analysis

The 5 Whys analysis started with Sakichi Toyoda, a Japanese inventor and founder of Toyota Industries. Toyoda believed that solving problems meant digging deep to find the real cause, not just fixing surface-level issues.

In the 1950s, this technique became a key part of the Toyota Production System, which was designed to make factories run smoothly and efficiently. Workers would ask “Why?” multiple times to figure out why a problem happened and how to prevent it from happening again. This wasn’t about blaming anyone but about improving processes and working smarter.

The 5 Whys became a powerful tool at Toyota, helping the company create better systems and a culture of continuous improvement. Over time, people outside of manufacturing saw how simple and effective it was, and it started being used in other areas like healthcare, software development, and everyday problem-solving.

What makes the 5 Whys special is its simplicity. It’s a method anyone can use to uncover the root cause of a problem, just by asking thoughtful questions. This idea, born in a factory, is now helping people and businesses around the world solve problems more effectively.

When to Use the 5 Whys Method

The 5 Whys technique is simple and effective, but it’s not always the right tool for every situation. Here are some scenarios where the 5 Whys can be particularly useful:

1. When you want to find the root cause of a problem

The 5 Whys is ideal for identifying the underlying cause of an issue. If you’re facing recurring problems or something that just doesn’t seem right, asking “Why?” multiple times helps dig deeper and get to the core of the issue.

2. For quick problem-solving in everyday situations

The 5 Whys is quick and simple, so it’s great for resolving problems that don’t require a lot of investigation or detailed analysis. If something isn’t working as expected, a few rounds of “Why?” can quickly help you identify a straightforward solution.

3. When you want to improve processes

The 5 Whys is a valuable tool when looking to improve existing processes. It helps to figure out what’s going wrong in a process and why, so you can fix it at the source rather than just addressing the symptoms.

4. To investigate quality issues

If there’s a quality issue with a product or service, the 5 Whys can help find the root cause. By asking “Why?” multiple times, you can dig into the problem and find out whether it’s a design issue, manufacturing problem, or something else entirely.

5. When you need to involve the team in problem-solving

The 5 Whys is great for team discussions. It encourages collaboration and different perspectives, which helps the team collectively understand the problem and come up with a solution.

6. In situations where you want a fast, low-cost solution

Unlike other techniques that require data analysis or complex tools, the 5 Whys is quick and doesn’t require a lot of resources. This makes it a cost-effective approach for solving smaller or simpler problems.

The Benefits of the 5 Whys Technique

The 5 Whys technique is simple, but it offers several powerful benefits that can help you solve problems more effectively and make lasting improvements. Here are the key advantages:

It helps uncover the root cause

Instead of just addressing the symptoms, the 5 Whys digs deep to find the real cause of the problem. This helps you avoid fixing something that will only come back later. By solving the root cause, you prevent the issue from reappearing.

It encourages critical thinking

The 5 Whys pushes you to think critically about what’s really going on. Each question makes you challenge assumptions and look at the situation from different angles, helping you understand the problem more thoroughly.

It’s simple and easy to use

One of the greatest benefits of the 5 Whys is how straightforward it is. You don’t need special tools or training to get started. Just ask “Why?” and write down the answers—it’s a quick, low-cost way to identify problems and solutions.

It improves team collaboration

Asking “Why?” with a group encourages open discussion and collaboration. It brings together different perspectives, helping to see the full picture and discover causes that might have been overlooked.

It helps prevent recurrence

By identifying and fixing the root cause, the 5 Whys help prevent problems from happening again. This leads to better processes and stronger systems that continuously improve over time.

It’s quick and efficient

You don’t need to spend hours analyzing the problem. The 5 Whys technique is fast, and it can often help you get to the root cause in just a few minutes. This allows you to act on solutions without wasting time.

Limitations of the 5 Whys Method

While the 5 Whys technique is useful, it’s not always perfect. There are some limitations to keep in mind, so you can use it effectively and know when it might not be enough.

It can oversimplify complex problems

Sometimes, problems have multiple causes that can’t be solved by just asking “Why?” a few times. If the issue is complicated, the 5 Whys might not be enough to uncover all the factors at play.

It can lead to incomplete answers

The method relies on the assumption that each “Why?” leads to a clear cause. However, sometimes the answers aren’t straightforward or might not point to the root cause, leading to confusion or incomplete conclusions.

It relies on the right people asking the questions

For the 5 Whys to be effective, the people involved need to have enough knowledge of the situation. If the team doesn’t fully understand the problem or its context, they might miss important causes or stop too early.

It may not identify systemic issues

The 5 Whys often focus on individual causes but might not uncover deeper, systemic issues within the organization or processes. These problems might require more in-depth analysis or different tools.

It can result in finger-pointing

If people aren’t careful, the 5 Whys method can unintentionally lead to blame. It’s important to keep the focus on finding solutions rather than assigning fault. If the team feels accused, they might become defensive and less open to solving the problem.

It may take too long in some cases

Though the 5 Whys is designed to be quick, sometimes it can take longer than expected, especially if the issue is more complex or the team struggles to reach a clear cause.

Tips for Effective Use of the 5 Whys

To get the most out of the 5 Whys technique, there are a few tips that can help you use it effectively. These will guide you to ask the right questions and reach useful, actionable insights.

Stay focused on the problem, not the people

The goal is to find the root cause, not to blame someone. Keep the questions focused on the issue itself, not on who made a mistake. This helps create a safe environment where everyone feels comfortable sharing and brainstorming.

Involve the right people

Make sure you have the right team involved in the process. The people closest to the problem, whether from different departments or with different expertise, will provide valuable perspectives and help uncover the real cause.

Dig deeper with each “Why?”

Don’t stop at surface-level answers. Each time you ask “Why?”, make sure the answer really explains something deeper. This might require rethinking your approach or asking more follow-up questions to uncover a cause that you hadn’t thought of.

Don’t get stuck on “5”

The technique is called the 5 Whys, but that doesn’t mean you have to stop at five questions. If you reach the root cause in fewer questions, great! If it takes more, that’s fine too. The goal is to keep asking until you uncover the real issue.

Use it in a group discussion

While it’s possible to do the 5 Whys on your own, it’s most effective when done in a group. This allows you to hear different perspectives and get more detailed answers. Collaboration helps everyone understand the issue better and come up with a stronger solution.

Document everything

Record each “Why?” and its answer. This documentation can help you keep track of the thought process and is useful if you need to revisit the issue later. It also helps keep everyone aligned on the problem and solution.

Take action once you find the root cause

Once you’ve identified the root cause, don’t just leave it at that. Use the insights to develop a solution and put it into action. If you don’t act on the findings, the problem is likely to occur again.

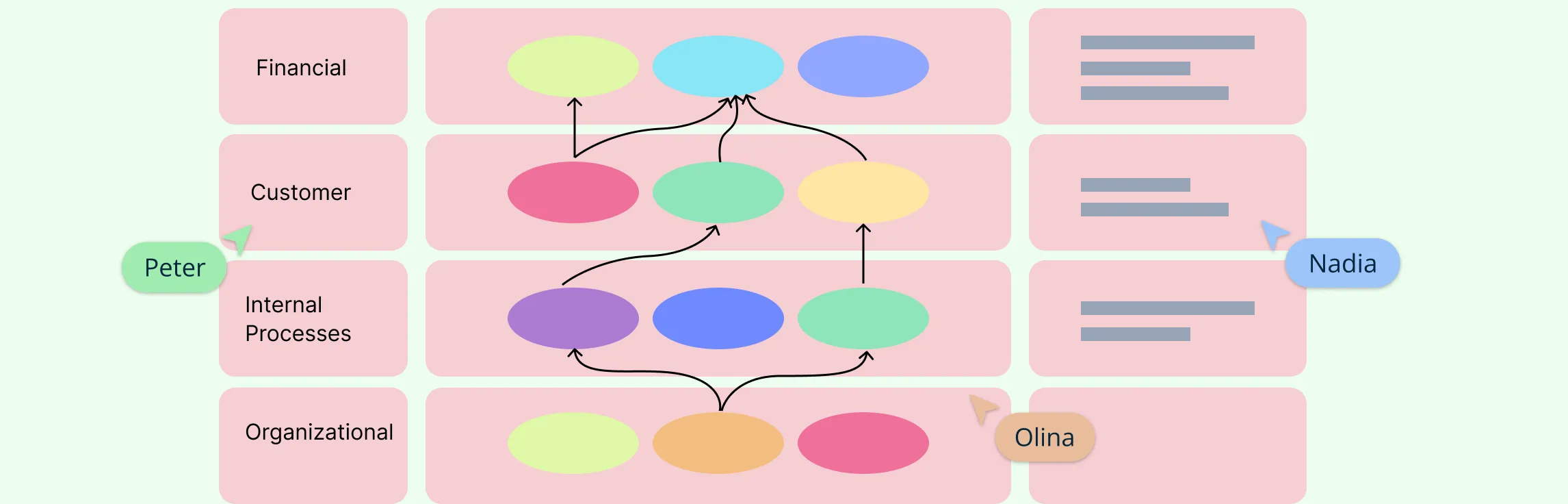

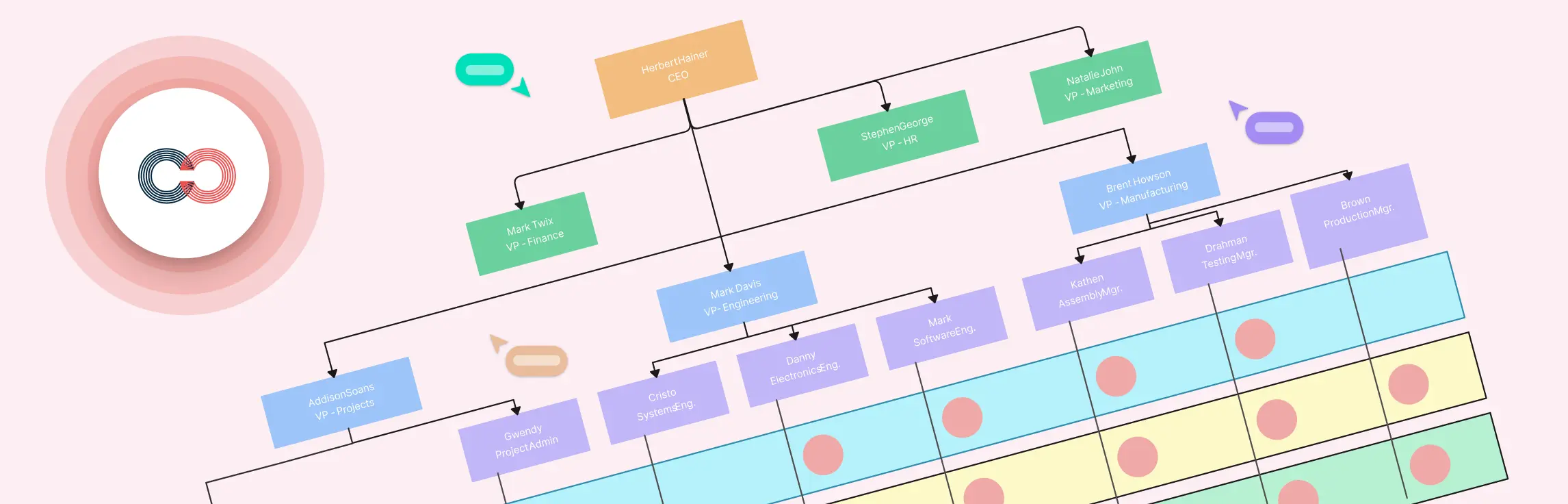

Simplify Your 5 Whys Analysis with Creately

Creately’s user-friendly interface, collaborative features, and customization options make it an ideal tool for conducting 5 Whys analysis. It not only simplifies the process but also ensures your findings are well-documented and actionable.

1. Start with a 5 Whys template: Creately provides pre-designed 5 Whys templates that help you get started quickly. The structured layout keeps your analysis organized and easy to follow.

2. Define the problem visually: Use Creately’s tools to add the problem at the top of the template. You can include notes, attach relevant documents, or add visuals for better clarity.

3. Collaborate in real-time: Creately’s collaboration features allow team members to work together seamlessly. Everyone can add their inputs, suggest edits, and track changes live, ensuring a thorough and inclusive analysis.

4. Ask “Why?” and map the answers: With Creately’s drag-and-drop tools and sticky notes, create a flow of answers directly on the diagram. Connect ideas easily with arrows and lines to keep the structure clear and logical.

5. Use presentation mode for discussions: Once the root cause is identified, use Creately’s presentation mode to share your findings with stakeholders. This makes discussions more interactive and helps in reaching decisions faster.

6. Document and share results: After completing the analysis, save it in Creately’s workspace. You can share it with others via a link or export it as a PDF or image for offline use.

Wrapping Up: The Power of the 5 Whys

The 5 Whys method is a simple yet powerful tool for uncovering the root cause of problems. By asking “Why?” multiple times, you can move past surface-level issues and uncover deeper insights that lead to lasting solutions.

Whether you’re solving everyday challenges, improving processes, or tackling complex problems, the 5 Whys technique helps you approach issues with clarity and purpose. It fosters collaboration, encourages critical thinking, and equips you to address problems at their core.

With its straightforward approach and versatility, the 5 Whys can become an essential part of your problem-solving toolkit, driving continuous improvement in both personal and professional settings.

References

Serrat, O. (2017). The five whys technique. [online] ResearchGate. Available at: https://www.researchgate.net/publication/318013490_The_Five_Whys_Technique.

Serrat, O. (2017). The Five Whys Technique. Asian Development Bank, [online] (30). Available at: https://www.adb.org/publications/five-whys-technique.

FAQs About the 5 Whys Analysis

Who can use the 5 Whys analysis?

How many “Whys” should I ask?

Can the 5 Whys method be used for complex problems?

Does the 5 Whys method always guarantee accurate results?

How can I make the 5 Whys analysis more effective?