Have you ever wondered how some companies consistently deliver high-quality products while operating at peak efficiency? Chances are they’re using methodologies like Six Sigma or Lean to achieve those results. In today’s competitive business world, where time and resources are limited, organizations are always looking for ways to streamline operations, cut waste, and improve quality. Six Sigma and Lean have become two of the most popular approaches for making this happen.

But what’s the difference between them? While both methodologies focus on improving efficiency and boosting productivity, they tackle the challenge from different angles. Six Sigma zeros in on reducing defects and minimizing variation, while Lean focuses on eliminating waste to create a more efficient workflow. This article will break down the key differences between Six Sigma and Lean, helping you understand which approach—or combination—might be best for your organization. Whether you’re managing a team or just curious about process improvement, this guide will give you the clarity you need

What are the Differences Between Six Sigma and Lean?

Understanding Six Sigma

Six Sigma is a data-driven approach designed to improve processes by reducing defects and minimizing variation. By leveraging statistical analysis, Six Sigma aims to achieve near-perfect quality, targeting only 3.4 defects per million opportunities. This methodology focuses on identifying and eliminating the root causes of errors and inefficiencies to enhance overall process performance.

The Six Sigma methodology was developed in the 1980s by Motorola engineer Bill Smith. It was later popularized by General Electric under Jack Welch’s leadership in the 1990s. The framework has since evolved, crossing from manufacturing into various sectors, including healthcare, finance, and IT, providing a robust foundation for quality improvement across industries.

Core Objectives of Six Sigma

Six Sigma aims to enhance quality and efficiency by rigorously measuring and analyzing data to identify process variations and their potential impacts. The primary objectives are:

Reducing Defects: Striving for minimal defects or errors.

Improving Process Consistency: Ensuring reliable and predictable processes.

Enhancing Customer Satisfaction: Delivering high-quality products and services.

Data-Driven Decision Making: Using statistical methods to guide business decisions.

Methodologies and Frameworks

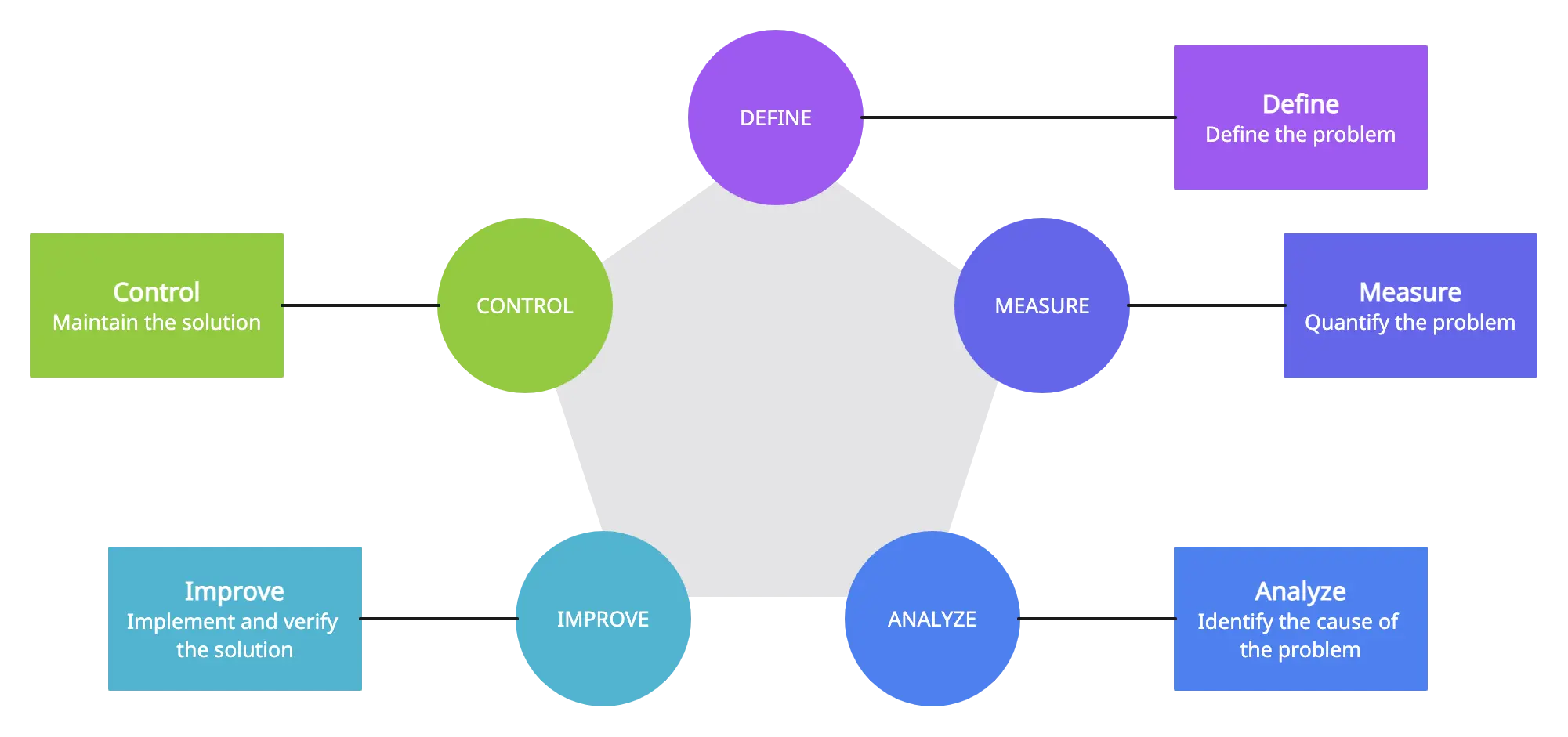

Six Sigma utilizes two key frameworks: DMAIC and DMADV.

- DMAIC: This acronym stands for Define, Measure, Analyze, Improve, and Control. DMAIC is employed for improving existing processes.

- DMADV: Stands for Define, Measure, Analyze, Design, and Verify. DMADV is used primarily for developing new processes or products to ensure they meet Six Sigma standards from the start.

Understanding Lean

Lean methodology is a systematic approach aimed at waste elimination and efficiency improvement in organizational processes. Derived from the Toyota Production System, Lean seeks to maximize value by minimizing non-value-adding activities, commonly referred to as waste. It is a customer-centric approach that strives for continuous improvements, creating more value for customers with fewer resources.

Originating from Toyota’s manufacturing philosophy in the mid-20th century, Lean principles have since been adopted across various industries beyond manufacturing, including healthcare, logistics, and service sectors. Toyota’s approach focused on streamlining production processes and eliminating waste, leading to the creation of a robust, efficient production system.

Principles of Lean Methodology

Value: Identifying what constitutes value from the customer’s perspective and focusing all efforts on maximizing this value.

Flow: Ensuring a smooth and uninterrupted flow of processes, minimizing delays and bottlenecks.

Pull: Implementing a pull system where production is based on actual customer demand, reducing overproduction and inventory costs.

Perfection: Continuously seeking to improve processes and eliminate waste, striving for perfection.

Frameworks Used in Lean

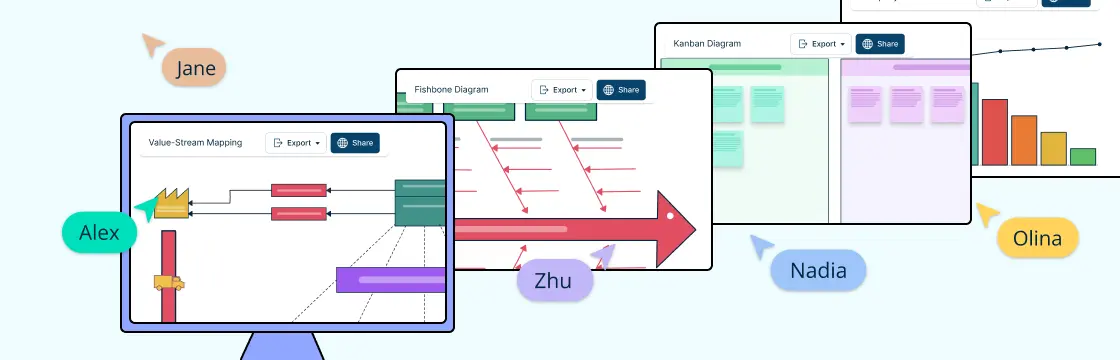

- Value Stream Mapping: Provides a visual representation of the steps involved in the process, identifying areas of improvement.

Just-In-Time (JIT): Produces what is needed, when it is needed, and in the amount needed, minimizing waste and inventory costs.

5S: A workplace organization method that uses five Japanese principles (Sort, Set in order, Shine, Standardize, Sustain) to improve efficiency.

Kanban: A scheduling system for lean and just-in-time production that uses visual cues to signal the need to move inventory.

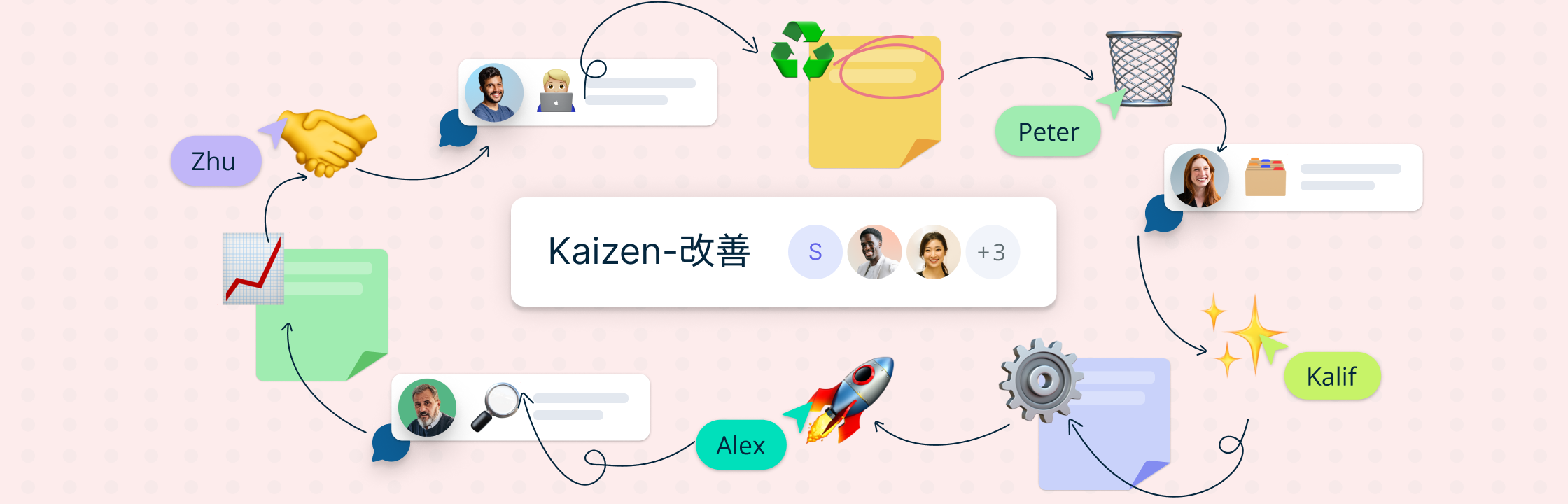

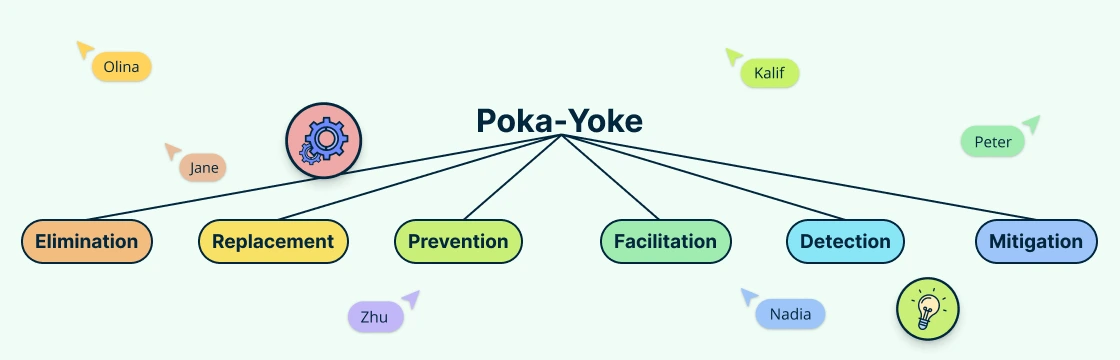

- Kaizen: A philosophy of continuous improvement where all employees are encouraged to suggest and implement small incremental changes in business processes.

Key Differences Between Six Sigma and Lean

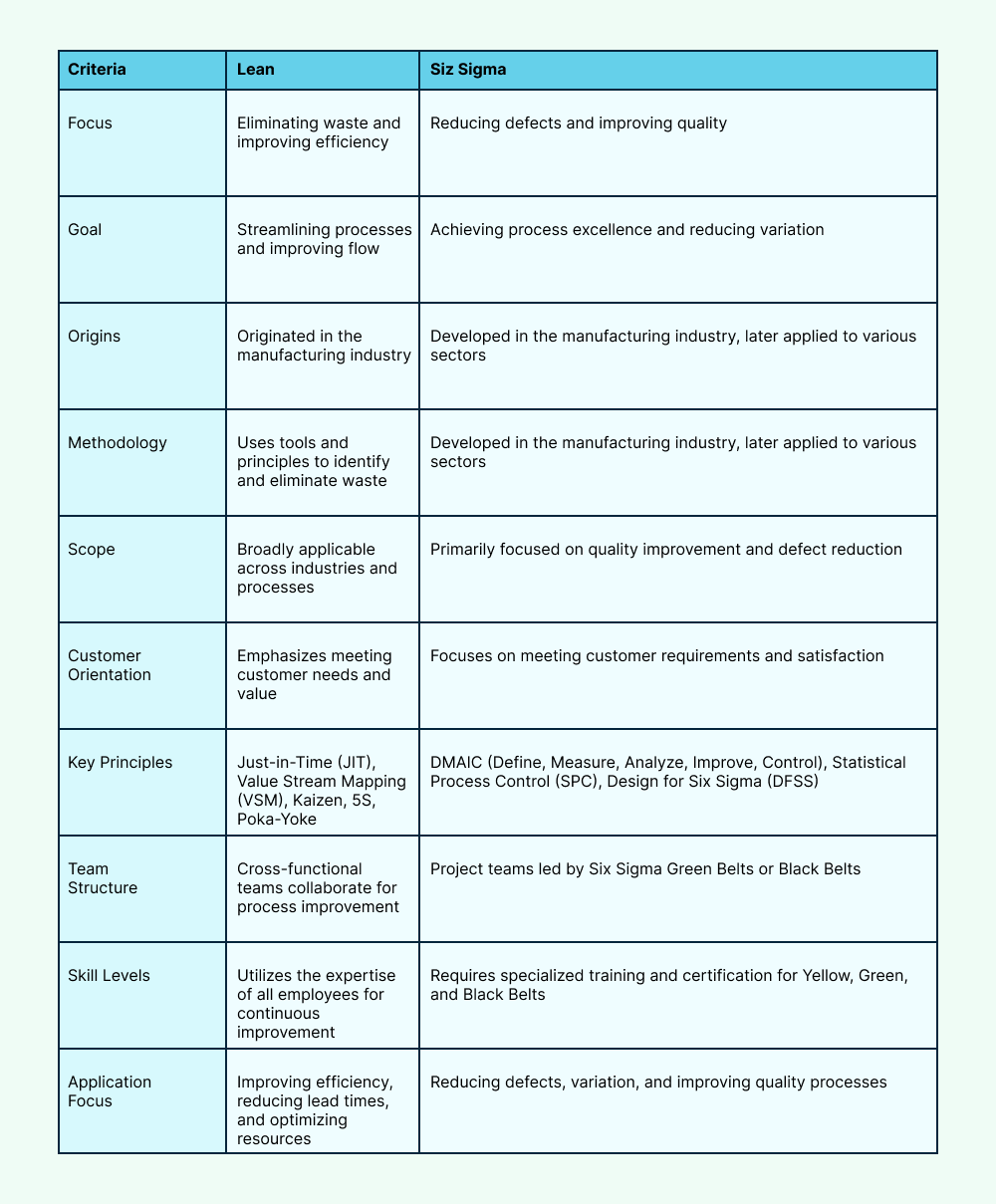

(graphic)

While both Six Sigma and Lean aim to improve organizational processes, they differ significantly in their focus, methodologies, principles, and applications.

Focus and Goals

Six Sigma: At the heart of Six Sigma is the drive to reduce process variation and defects, with a laser-like focus on quality. It targets a statistical threshold of no more than 3.4 defects per million opportunities (DPMO), which equates to near-perfect quality. This emphasis on precision makes Six Sigma particularly valuable in industries like manufacturing, healthcare, and finance, where a small defect can have significant consequences. For example, in healthcare, minimizing errors in medication dosage or surgical procedures is critical. Six Sigma’s focus is on delivering consistent, reliable outcomes, which is why it’s often referred to as a “quality improvement” methodology.

Lean: Lean’s goal is to create value by eliminating waste in processes. Waste, in Lean terminology, refers to any activity that does not directly add value to the customer. This could mean excess inventory, unnecessary movement of materials, overproduction, waiting time, or even underutilized talent. Lean focuses on making processes as efficient and streamlined as possible, ensuring that every step in the process adds value. Lean is applicable in any industry where time and resources are crucial—whether in manufacturing, logistics, service industries, or even creative fields. For example, in a hospital setting, Lean can help reduce patient wait times by eliminating bottlenecks in patient flow, ultimately enhancing the patient experience.

Approach

The principles of Six Sigma and Lean are rooted in a deep understanding of how to optimize processes, reduce waste, and deliver maximum value to customers. These methodologies evolved from different backgrounds - Six Sigma from quality control in manufacturing, and Lean from the efficiency-focused Toyota Production System - but they share a common goal of operational excellence.

The thinking behind Six Sigma principles centers on the idea that by rigorously measuring and analyzing processes, organizations can identify and eliminate sources of variation that lead to defects. This data-driven approach aims to create highly predictable and consistent outcomes, ultimately resulting in improved quality and customer satisfaction.

Lean principles, on the other hand, are built on the philosophy of maximizing value while minimizing waste. The core thinking here is that by clearly understanding what customers truly value, organizations can streamline their processes to deliver just that, eliminating any activities or resources that don’t contribute directly to this value creation.

Both methodologies emphasize continuous improvement, but they approach it from slightly different angles. Six Sigma focuses on reducing variability and defects to near-zero levels, while Lean concentrates on creating smooth, efficient workflows that respond dynamically to customer needs.

Together six sigma and lean form a comprehensive framework for process optimization, encouraging organizations to simultaneously pursue perfection in quality and efficiency. This holistic approach recognizes that true operational excellence comes not just from eliminating errors, but from fundamentally rethinking how value is created and delivered to customers.

Application And Scope

Six Sigma: Six Sigma’s precision and focus on reducing defects make it especially valuable in industries that require high levels of quality control. For instance:

Manufacturing: In production environments where minute errors can lead to significant losses, Six Sigma helps companies like Motorola and General Electric maintain stringent quality standards.

Healthcare: In healthcare, Six Sigma can help reduce variability in patient care, leading to improved outcomes and reduced medical errors.

Finance: In the finance industry, where accuracy is paramount, Six Sigma methodologies help organizations minimize errors in transactions, improve customer service, and streamline processes like loan approvals.

Lean: Lean’s flexibility allows it to be applied across a broad range of industries, not just manufacturing:

Service Industries: In sectors like hospitality or retail, Lean helps streamline operations and reduce wait times, leading to better customer experiences.

Healthcare: Lean has been used to improve patient flow in hospitals, reduce wait times, and enhance the efficiency of surgeries and other procedures.

Office and Administrative Settings: Lean can be applied to back-office functions to reduce wasted time and resources, improve employee efficiency, and speed up administrative processes like document approvals or data entry.

Synergies Between Lean and Six Sigma

Six Sigma and Lean complement each other in several ways, offering synergies that enhance process efficiency, quality, and customer satisfaction. Here are some key synergies:

Enhanced Process Efficiency: Lean focuses on optimizing process flow and eliminating waste, while Six Sigma aims to reduce process variation and defects. Together, they create highly efficient, error-free processes.

Quality and Consistency: Lean principles help maintain a smooth production flow and minimize waste, while Six Sigma ensures that the end products are of high quality and meet customer specifications consistently.

Customer Satisfaction: By integrating Lean’s emphasis on value addition with Six Sigma’s focus on defect reduction, organizations can significantly enhance customer satisfaction and loyalty.

What is Lean Six Sigma?

Lean Six Sigma is a powerful, integrated approach that combines Lean manufacturing and Six Sigma methodologies to enhance organizational processes and maximize efficiency. At its core, Lean Six Sigma focuses on delivering greater value to customers by eliminating waste and reducing defects. Lean principles target non-value-adding activities to streamline workflows, while Six Sigma emphasizes minimizing process variation and ensuring consistent quality through data-driven analysis. The framework often utilizes the DMAIC methodology—Define, Measure, Analyze, Improve, and Control—to guide teams in systematic problem-solving. Tools like Value Stream Mapping help visualize process flows and identify bottlenecks, while the 5S system (Sort, Set in order, Shine, Standardize, Sustain) fosters a clean and organized workspace. By combining qualitative insights from Lean with quantitative methods from Six Sigma, organizations can achieve enhanced efficiency, improved quality, and significant cost reductions. Lean Six Sigma also empowers employees by fostering a culture of collaboration and continuous improvement, encouraging contributions from all levels. Ultimately, this holistic approach promotes sustainable improvement and equips organizations with the strategies needed to thrive in a competitive landscape, making it a valuable framework across various industries, including manufacturing, healthcare, and services.

How to Choose Which Framework to Use

Assessing Organizational Needs

When selecting between Lean and Six Sigma, understanding your organization’s specific needs is the starting point. Lean is ideal for organizations looking to streamline processes, eliminate waste, and maximize efficiency swiftly. In contrast, Six Sigma works best for businesses that aim to minimize defects and improve quality through data-driven decision-making. Evaluating the primary pain points in your processes will help determine which framework aligns better with your objectives.

Considerations for Industry Applications

The application scope for Lean and Six Sigma differs across industries. Lean principles are more broadly applicable, perfect for environments where rapid improvement and waste reduction are critical, such as manufacturing, healthcare, and services. Conversely, Six Sigma is particularly effective in sectors where quality and precision are paramount, such as finance, healthcare, and specialized manufacturing. Evaluate the specific demands and requirements of your industry to make an informed choice.

Long-Term Goals

Aligning with your long-term goals is crucial when choosing between Six Sigma and Lean . If your focus is on achieving continuous improvement and fostering a culture of innovation, Lean may be more suitable. However, if your strategic objective is to achieve high levels of quality and customer satisfaction through rigorous data analysis, Six Sigma would be the appropriate choice. Remember, setting clear, long-term objectives will guide the successful implementation of either methodology.

Hybrid Approach

Many organizations find that a hybrid approach—Lean Six Sigma—leveraging both methodologies’ strengths, offers a comprehensive solution to process improvement. This combined framework can address a broader range of operational challenges by integrating Lean’s waste elimination with Six Sigma’s defect reduction strategies.

Lean Six Sigma: Combines the best of both methodologies for enhanced efficiency and quality.

Holistic Improvement: Addresses both waste and defects, providing a balanced approach to process optimization.

Ultimately, understanding your organizational needs, industry demands, and long-term goals will empower you to choose the most suitable framework, ensuring sustainable growth and improvement. To see how the right framework can make a significant difference, explore how Creately supports both Lean and Six Sigma through its comprehensive features and collaborative tools.