In the fiercely competitive environment of modern business, organizations constantly seek ways to improve efficiency and reduce waste. Continuous improvement plays a pivotal role in this endeavor by methodically integrating with existing business processes. For companies aiming to stay ahead, this approach serves as an indispensable tool for streamlining operations, enhancing product quality, and ultimately boosting profitability.

The core of continuous improvement lies in its ability to bring about substantial cultural transformations within an organization. When fully embraced, it fosters a work environment where every team member is motivated to engage proactively in problem-solving and process enhancement. This heightened level of employee engagement can lead to increased morale and job satisfaction, which are crucial elements in sustaining productivity and innovation.

What is Continuous Improvement?

Continuous improvement is a systematic, ongoing approach to enhancing the quality, efficiency, and effectiveness of an organization’s processes, products, or services. At its core, it’s a philosophy that emphasizes the importance of making small, incremental changes over time rather than implementing large-scale transformations all at once. This approach is based on the belief that consistent, small improvements can lead to significant long-term benefits.

The concept originated in manufacturing but has since been adopted across various industries. It involves all levels of an organization, from frontline workers to top management, in identifying and implementing improvements. Key methodologies associated with continuous improvement include Lean, Six Sigma, and Kaizen.

Continuous improvement is characterized by:

Regular assessment of current processes

Identification of areas for enhancement

Implementation of changes

Measurement of results

Iteration based on feedback and outcomes

By fostering a culture of continuous improvement, organizations can adapt more readily to changing market conditions, enhance customer satisfaction, and maintain a competitive edge in their industry

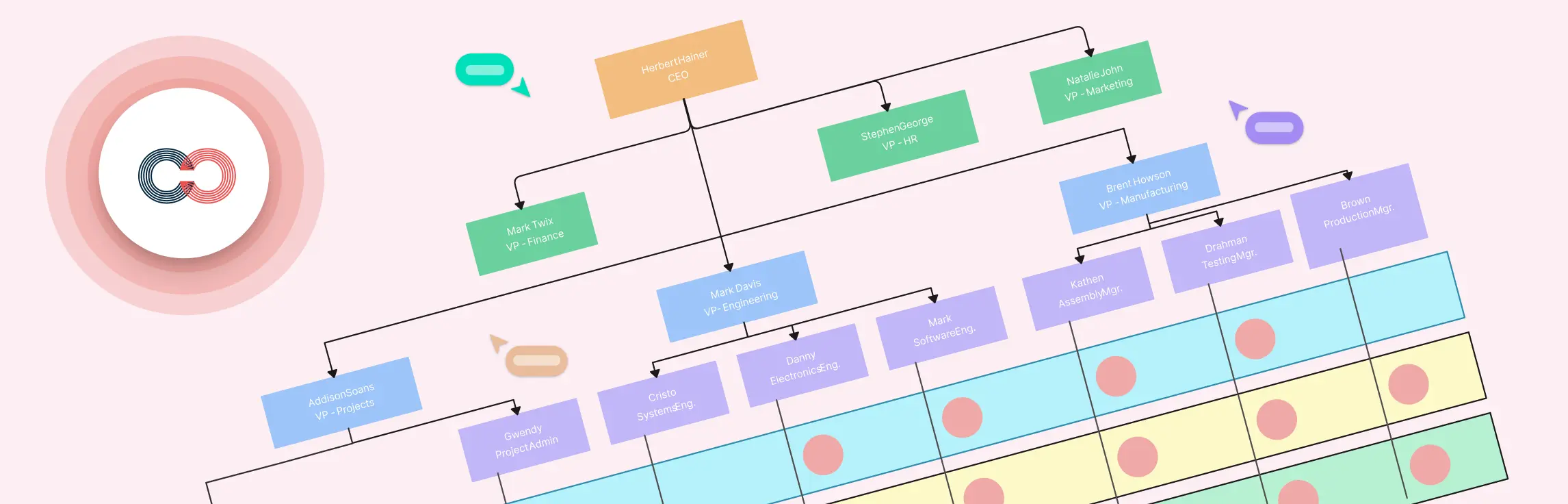

Management plays a crucial role in sustaining a continuous improvement culture. Their commitment is vital in endorsing the necessary resources and support for ongoing initiatives. When leaders actively participate in and support these efforts, it not only strengthens the process but also signals to employees that improvement is a key strategic priority.

Continuous improvement is an essential philosophy that not only optimizes operations but also significantly enhances productivity and quality across industries. This section delves into the multifaceted benefits of continuous improvement, offering insights into its potential to transform your organization’s performance.

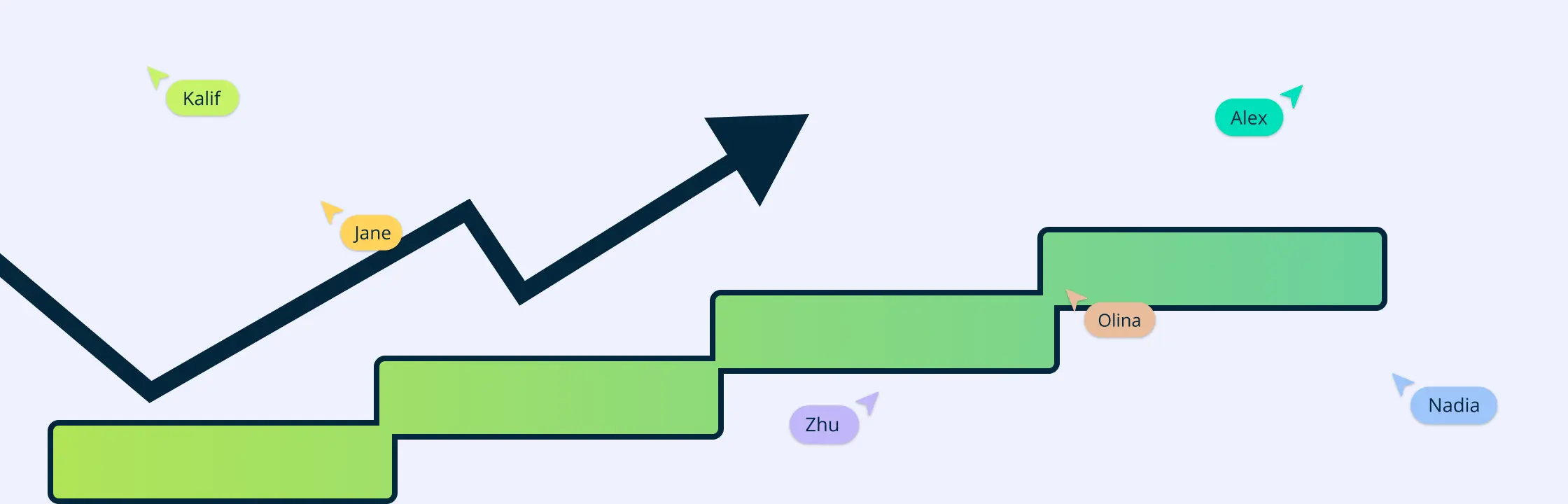

How to Implement Continuous Improvement in 6 Steps

Implementing a solid strategy for continuous improvement can transform team performance and elevate business operations. This section outlines key steps to effectively integrate continuous improvement within any organization.

1. Assess Your Current State

Start by conducting a thorough analysis of current processes. Gather data on performance metrics and workflow efficiencies to identify existing challenges and areas that need enhancement. This assessment establishes a baseline, helping you monitor progress over time.

2. Identify the Root Cause of Problems

Once you’ve assessed the current state, focus on pinpointing the root causes of inefficiencies or defects. Leveraging tools like the 5 Whys technique can be highly effective in uncovering the fundamental issues impacting your processes. This analysis ensures that you focus on the core issues, not just symptoms.

3. Develop a Solution

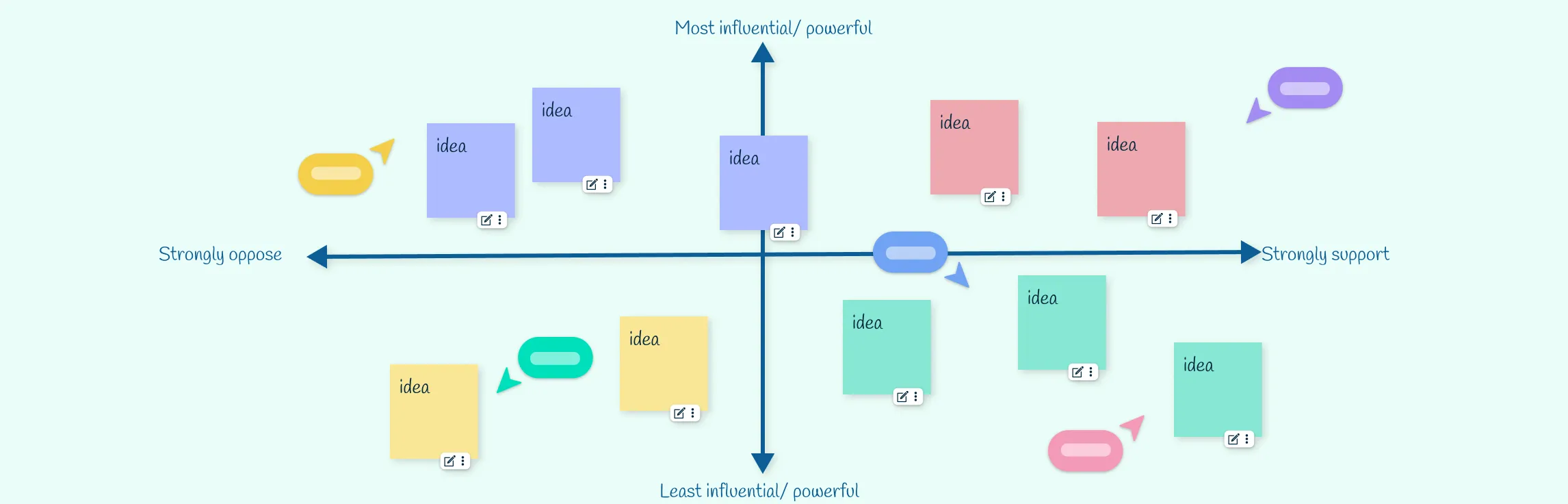

After identifying the root causes, brainstorm potential solutions with your team. Involving multiple stakeholders fosters diverse perspectives and innovative ideas. Ensure that proposed solutions align with your organization’s strategic objectives and operational constraints.

4. Implement the Plan

Begin implementing the chosen solution on a small scale to manage risk and gather actionable insights. This phase involves applying the PDCA cycle (Plan-Do-Check-Act) methodology to roll out improvements systematically and evaluate their effectiveness before broader implementation.

5. Evaluate

After implementation, evaluate the results to determine the impact of changes made. Collect data and analyze whether improvements have positively influenced performance metrics, reducing waste and enhancing efficiency. This step is crucial as it provides feedback for refinement.

6. Create Processes for Sustained Improvement

Ensure that improvements are sustained by institutionalizing new processes. Document changes, update standard operating procedures, and establish regular review cycles. Continuous improvement should be an ongoing effort, with adaptability to changing demands.

Implementing continuous improvement effectively can result in significant gains in efficiency, quality, and team morale. By following these steps and utilizing tools like Creately, organizations can visualize processes and collaborate efficiently to optimize workflows.

The Three Key Aspects of Continuous Improvement

Continuous improvement is a strategic approach that focuses on enhancing organizational performance through three critical dimensions: process, product, and people. By systematically addressing these interconnected areas, businesses can drive innovation, efficiency, and sustainable growth.

Process Improvement

Process improvement involves meticulously examining and refining the workflow, methods, and procedures used to deliver products or services. This aspect focuses on:

Identifying inefficiencies and bottlenecks

Streamlining operational procedures

Reducing waste and unnecessary steps

Implementing more effective work methodologies

Enhancing overall operational efficiency

Product Improvement

Product improvement centers on continuously analyzing and enhancing the product or service offering. This dimension includes:

Evaluating current product features and functionality

Gathering and incorporating customer feedback

Identifying potential design innovations

Addressing performance limitations

Staying ahead of market trends and competitive offerings

People Improvement

People improvement recognizes that human capital is the most valuable asset in any organization. This aspect emphasizes:

Continuous skill development and training

Creating a culture of learning and growth

Empowering employees with new knowledge

Encouraging innovation and creative problem-solving

Developing leadership and collaborative capabilities

By holistically addressing process, product, and people improvements, organizations can create a dynamic environment of ongoing enhancement, adaptability, and competitive advantage.

Benefits of Continuous Improvement

Enhanced Quality and Customer Satisfaction

Continuous improvement leads to a consistent focus on enhancing product and service quality, resulting in higher customer satisfaction. By implementing regular feedback loops, organizations can quickly identify and address customer pain points. This proactive approach to quality management results in fewer defects and a better overall customer experience. As processes are refined and optimized, the end products or services naturally improve, leading to increased customer loyalty and positive word-of-mouth recommendations.

Increased Employee Engagement and Morale

One of the key benefits of continuous improvement is its positive impact on employee engagement and morale. By empowering employees to contribute ideas and drive change, organizations foster a sense of ownership and pride in their work. This approach creates a culture where every team member feels valued and heard. Additionally, the focus on continuous learning and development keeps employees motivated and engaged, as they see clear pathways for personal and professional growth within the organization.

Agility and Adaptability

Continuous improvement develops an organization’s capacity for change, making it more agile and adaptable to market shifts. By constantly evaluating and refining processes, companies build a proactive approach to problem-solving. This agility allows organizations to respond quickly to unexpected challenges and capitalize on new opportunities. The result is a more resilient business that can navigate the complexities of today’s fast-paced business environment with greater ease and success.

Competitive Advantage

Organizations that embrace continuous improvement often gain a significant competitive advantage in their industry. By staying ahead of industry trends and continuously refining their processes, these companies can achieve unique operational efficiencies that are difficult for competitors to replicate. The culture of excellence fostered by continuous improvement becomes a key differentiator, allowing the organization to stand out in a crowded marketplace and attract both customers and top talent.

Sustainable Growth

The focus on steady, incremental improvements rather than short-term fixes promotes sustainable growth within an organization. By building a solid foundation of efficient processes and engaged employees, companies can scale their operations more effectively. This approach reduces the risk of burnout that often comes with constant major overhauls and allows for more controlled, manageable growth. Over time, the cumulative effect of these small improvements can lead to significant advancements and a stronger market position.

Enhanced Safety and Risk Management

Continuous improvement plays a crucial role in enhancing workplace safety and risk management. Regular process reviews help identify potential safety hazards before they become serious issues. This proactive approach fosters a culture of vigilance where all employees are encouraged to report and address safety concerns. As a result, organizations often see a reduction in workplace incidents and associated costs, leading to a safer work environment and potentially lower insurance premiums.

Helpful Resources

PDCA cycle examples to inspire your continuous improvement efforts and transform your organization's processes.

Visual tools and templates to successfully determine the root causes of issues via thorough analysis.

Unlock the power of continuous improvement by mastering the Kaizen principles and transforming your organization’s efficiency and culture.

Discover the power of the Kaizen method to achieve continuous improvement.

Difference Between Continuous Improvement and Continuous Delivery

Continuous improvement focuses on the incremental enhancement of processes, products, or services. This approach is broad, however, its application is not limited to the software industry. Whereas, continuous delivery specifically deals with the rapid and seamless release of software updates and new features. These two concepts, although related, target different outcomes.

Here is a comparative overview:

| Feature | Continuous Improvement | Continuous Delivery |

| Objective | Enhancing efficiency and minimizing waste across processes | Ensuring smooth, consistent deployment of software |

| Application | Broad application across various industries | Narrow application focused on software development |

| Methodologies | Utilizes tools like Lean and Kaizen for process optimization | Uses agile practices for faster and more reliable software releases |

While building an agile team allows for improved engagement in both continuous improvement and continuous delivery processes, the frameworks and tools employed may vary, dictated by the distinct requirements of each goal. Understanding the unique features of these methodologies is essential for organizations aiming to leverage their benefits efficiently. For more detailed insights, refer to context diagrams that prominently illustrate the application of these methodologies.

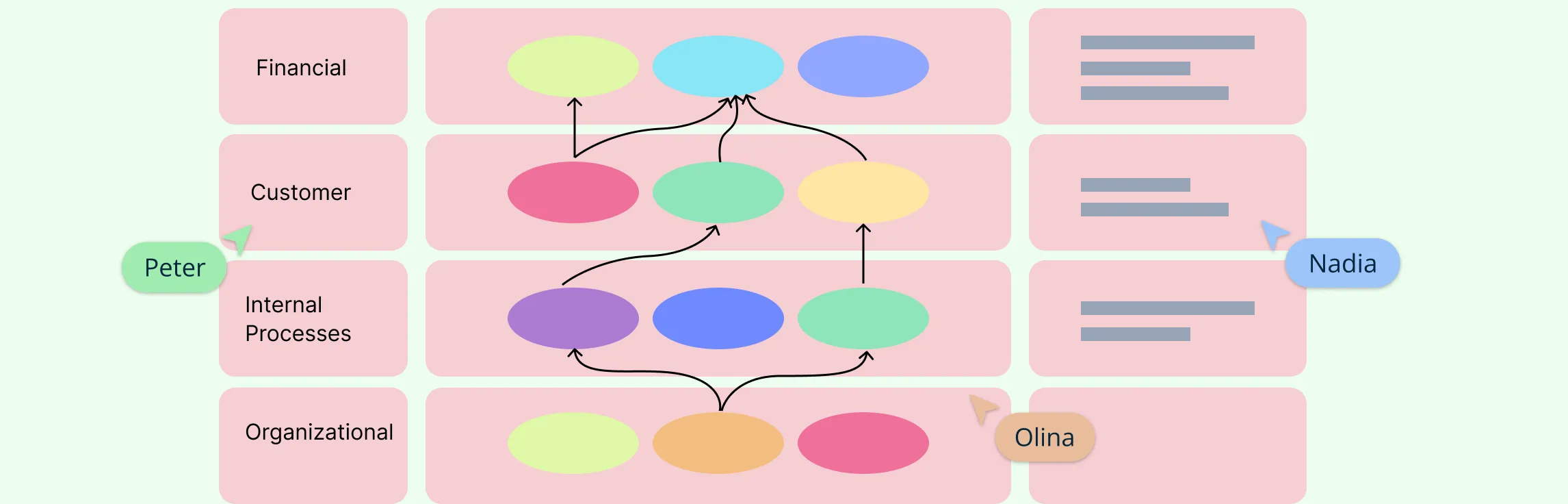

The Main Components of Continuous Improvement

The PDCA (Plan-Do-Check-Act) cycle is a cornerstone methodology in continuous improvement, providing a structured framework for implementing changes and analyzing their

effectiveness. By constantly looping through these four stages, companies can initiate incremental changes that lead to significant efficiency and productivity gains over time. This cycle is not just about planning and executing improvement strategies; it’s a disciplined approach that integrates feedback and subsequent modifications to ensure that each iteration brings tangible benefits.

Plan: In this stage, organizations seek out opportunities for improvement, establishing clear objectives and determining the required actions. This phase often involves thorough research and hypothesis formulation concerning potential interventions.

Do: Here, plans are put into action on a small scale to test their effectiveness. Real-world application of these plans provides immediate insights and feedback necessary for refining approaches and techniques.

Check: Analyzing the data derived from the ‘Do’ phase ensures that outcomes match expectations. This involves rigorous evaluation metrics to assess whether desired changes contribute positively to the strategic goals.

Act: Based on analysis, if the modification leads to desired outcomes, it is implemented on a broader scale. If not, the cycle begins anew, with revisions based on learned experiences.

Tools For Effective Continuous Improvement

Continuous improvement is the lifeblood of any successful organization, providing a strategic approach to refining processes, enhancing product quality, and optimizing resource usage. Various methodologies contribute to the effectiveness of continuous improvement within a business setting. Below, we delve into some key methods that facilitate this process:

- Lean: Born from the manufacturing genius of Toyota, Lean is a methodology focused on waste elimination and efficiency enhancement. It emphasizes value creation for the customer with minimal waste. Lean tools such as 5S (Sort, Set in order, Shine, Standardize, Sustain) and Value Stream Mapping aid in identifying waste and streamlining production processes.

- Kanban: Originating from Lean, the Kanban method improves work efficiency through visual management. It utilizes boards with columns representing different stages of a workflow, allowing for easy visualization of tasks. This helps teams to better manage flow, understand load capacity, and identify bottlenecks in processes.

Six Sigma: Six Sigma is a data-driven approach aimed at process perfection. It employs statistical tools to identify and remove defects, minimize variability, and enhance quality. The DMAIC (Define, Measure, Analyze, Improve, Control) methodology is cardinal to Six Sigma, ensuring systematic problem-solving for process improvement.

Total Quality Management (TQM): TQM integrates quality management principles into the fabric of an organization, emphasizing customer satisfaction, employee involvement, and continuous improvement. This all-encompassing approach involves every employee and department, striving for a culture of quality at every level.

Agile: Often used in software development, Agile frameworks such as Scrum and Extreme Programming (XP) facilitate a responsive, iterative approach to project management. By breaking projects into small increments and adapting to client feedback, Agile supports incremental improvements and swift adaptability.

Each of these methodologies offers unique tools and frameworks that can be tailor-fit to a company’s specific needs, ensuring that the continuous improvement efforts are aligned with overall business goals.

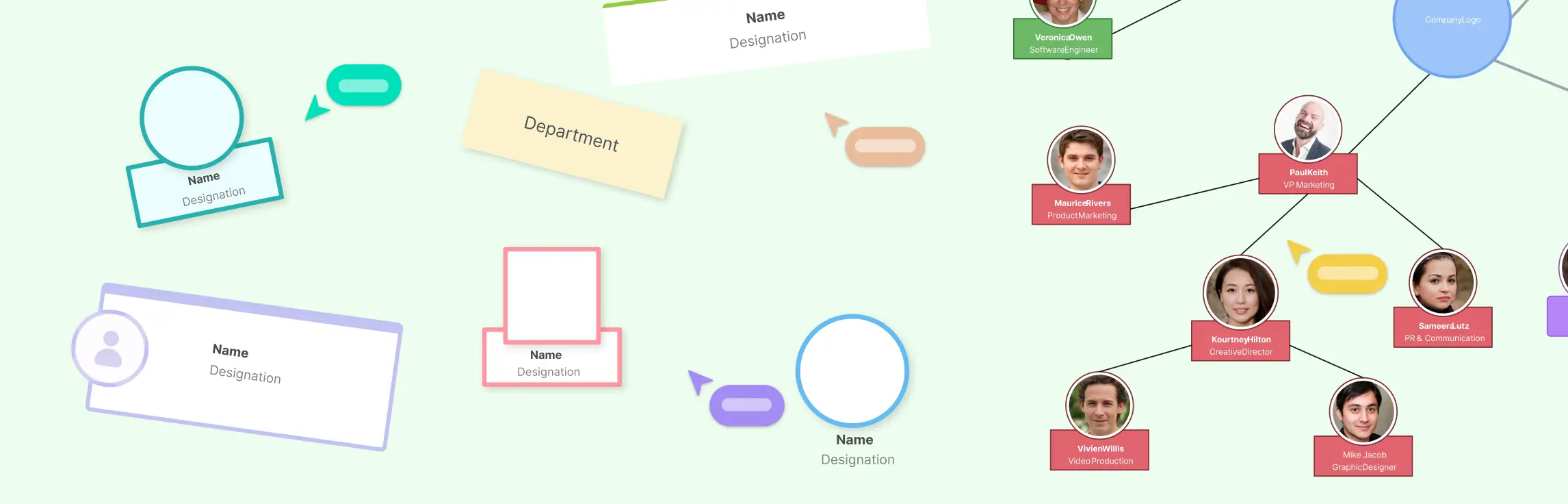

For teams seeking to enhance their continuous improvement capabilities, tools like Creately provide powerful visual process mapping capabilities. With Creately, teams can enhance visualization, collaboration, and real-time updates to optimize their continuous improvement endeavors.

Implementing a solid strategy for continuous improvement can transform team performance and elevate business operations. This section outlines key steps to effectively integrate continuous improvement within any organization.

The true power of continuous improvement lies in its ability to transform organizational culture. It’s about fostering an environment where every team member, from the frontline to the C-suite, is empowered to contribute to the company’s evolution. This collective commitment to progress creates a ripple effect, enhancing not only processes and products but also employee satisfaction and customer loyalty.

As we look to the future, the principles of continuous improvement will become increasingly vital. In a world where change is the only constant, the ability to adapt and innovate continuously will separate industry leaders from the rest. Organizations that successfully integrate these methodologies into their DNA will find themselves well-equipped to navigate challenges, seize opportunities, and drive sustainable growth.

The journey of continuous improvement is ongoing, but its rewards are immeasurable. It’s time for every organization to embrace this powerful philosophy and unlock its full potential.

Sources

“Continuous Improvement Model - Continual Improvement Tools | 2024, www.asq.org/quality-resources/continuous-improvement?srsltid=AfmBOoo90asHU5Dy2inhtxVQCGfAYOClrju6sCc5h6mpOZufvCPKjGlt.

FAQs

What is the 4-step continuous improvement model?

The 4-step continuous improvement model refers to the PDCA cycle, also known as Plan-Do-Check-Act. This model helps teams continuously improve by following these steps:

- Plan: Identify a problem or area for improvement and create a plan for testing solutions.

- Do: Implement the plan on a small scale and collect data.

- Check: Analyze the results to determine if the solution worked.

- Act: Standardize the successful improvement or return to planning if it needs adjustments.

What is Six Sigma’s role in continous improvement?

What continous imrpvement tools can be used in the Analyze phase?

In the Analyze phase of continuous improvement (often used in Six Sigma), the following tools are commonly used to understand the root cause of problems:

- Fishbone Diagram – Helps identify potential causes of a problem.

- 5 Whys – A simple method to dig deeper into the root cause by asking “why” multiple times.

- Pareto Chart – A tool that highlights the most significant causes contributing to the majority of problems, following the 80/20 rule.

What is a root-cause analysis in continous improvement?

Several continuous improvement tools are used for root-cause analysis, but the most common are:

- 5 Whys – A straightforward tool that helps drill down to the root cause by repeatedly asking why a problem is occurring.

- Fishbone Diagram – Also known as a Cause-and-Effect Diagram, this tool organizes potential causes of a problem into categories for easier analysis.